Expert article

Beyond the dew-point value: How to ensure high-quality dry compressed air in your process

Ensuring dry compressed air isn't about dew-point values alone. High-quality compressed air requires three things: good measurement practice, best-practice sensor installation, and smart sensor placement. Get these factors right, and you’ll maintain product quality, protect equipment, and increase energy efficiency.

Why moisture in compressed air matters

The compressed air used in many industrial applications needs to be kept dry. This is because moisture in compressed air can cause corrosion, blocked valves, frozen lines, product contamination, and microbial growth. If compressed air isn’t dry, it can quickly move from being a clean and reliable ‘fourth utility’ into posing a quality and maintenance risk.

There are different ways to measure the dryness of compressed air, but not all methods are equal.

Relative humidity (RH), for example, tells you the percentage of water relative to what the air can hold at that temperature. However, RH changes with temperature, so it doesn’t give a meaningful indication of condensation risk in a compressed air system.

Dew point, on the other hand, tells us the exact temperature at which moisture will condense into liquid water or ice. It is pressure dependent and shows us where and when in the process there could be a risk of moisture forming in the compressed air. This makes it the ideal control variable: if the dew point is above 0°C there is a risk of condensation and corrosion in your process. The lower the dew point, the safer it is.

Typical dew-point targets by dryer type include:

- Refrigerant dryer: ~+5°C

- Desiccant dryer: ~-40°C or lower

How to measure dew point correctly

Because dew point is pressure dependent, compressing air makes a difference to the measurement. It is important to take this into account if you are bleeding air to the atmosphere before measuring, as the dew point at the measurement point will be different from the dew point in the process. When pressure dew point is needed, either measure at process pressure or make sure you correct the measurement carefully.

A low dew point reading isn’t helpful if the measurement doesn’t reflect your actual process conditions.

Three simple steps to measure dew point correctly

- Select an instrument with the correct measuring range.

- Understand the pressure characteristics of the instrument. For example, some instruments on the market can’t measure at process pressure so the measurement will need to be corrected to discover the pressure dew point.

- Install the sensor correctly, following the manufacturer’s instructions. Do not install dew point sensors at pipe dead ends where there is no airflow.

Where to measure dew point

Sensor placement matters when measuring dew point. If you just install a sensor after the dryer and nowhere else, the measurements will only confirm that the dryer output is within parameters. It’s best to also place sensors at critical use and end-of-line points. This will reveal any leaks as well as losses from cooling and distribution.

For example, Walki Oy Valkeakoski uses a monitoring setup with sensors post-dryer and at the end of the compressed air network. This enabled real-time alerts when a dryer malfunction caused a rise in moisture levels. The system triggered an automatic alarm when the dew point in the compressed air network reached -25°C. This alarm meant Walki could respond quickly to the problem, preventing the issue from negatively impacting their production process.

Five installation essentials for accurate dew point measurement

Even the best dew point sensor will only be as accurate as the installation allows. Here is a handy checklist of five installation essentials to make sure your dew point measurements are as accurate as possible.

- Use the right materials. Ideally choose stainless steel with a good surface finish for piping and components. Avoid hygroscopic plastics and rubber as they can absorb moisture and then desorb it into the air. PTFE is an exception for temperatures down to around -40°C, because it has very low moisture absorption compared to other plastics.

- Ensure connections are leak tight. Dew point measurements are highly sensitive to even the smallest leaks in the system. All connections should be tight and sealed correctly – for tapered threads like NPT, PTFE tape is recommended. For straight thread connections like G½", the sealing washer provided with the instrument should be installed between the probe and the sample cell.

- Maintain steady flow. Dew point sensors need a slight but continuous flow across the sensing element to give an accurate reading. Higher flow rates generally improve the sensor response time, but flows of 1–2 l/min are typically enough for high-quality sensors. Don’t install sensors in dead ends with no airflow and be sure to purge sample lines before measuring.

- Avoid condensation in the sample line. The entire sampling line including valves and fittings needs to be kept above the process dew point to prevent liquid water. Use heated or trace-heated lines if needed.

- Use the right measurement setup. Direct inline installation is fine if the airflow is adequate and the temperature is close to ambient. A sampling cell offers protection to sensors during hot gas or water spikes and allows sensor servicing under pressure.

Which is better, spot checking or continuous monitoring?

Both methods have a purpose – spot checks can help solve issues, while continuous monitoring helps prevent them.

Spot checking using a portable dew-point probe and logger is ideal for performing audits, troubleshooting, and calibration checks. Energy savings can often come from finding and fixing leaks and right-sizing drying. For example, SmartAir and Energy Oy uses the Vaisala Indigo80 to generate energy and cost savings for customers that use compressed air.

Continuous monitoring gives you real-time situational awareness and enables automatic alarms if the dew point drifts or spikes. Drifts or spikes can be a sign of a dryer malfunction, tower switching, or a sudden load change. For example, at Walki’s Valkeakoski plant, sensors triggered an alarm when the dew point climbed to –25°C. This enabled quick corrective action before the change affected product quality. Continuous monitoring also provides useful trend data that you can use for maintenance and investment planning.

What are the relevant quality frameworks for compressed air?

The main ISO standard for measuring the purity of compressed air is ISO 8573, which divides compressed-air quality into classes for particles, water, and oil. The standard covers nine areas, including contaminants and purity classes, as well as the actual test methods for a wide range of variables including oil, gases, water, and humidity. Dew point measurement is how you prove compliance with the water component of the standard.

For hygiene-critical industries where there is a microbial growth risk, ISO 8573-7 covers viable contaminants. The dryness and cleanliness of compressed air is one of the primary barriers against microbial growth.

The benefits of modern dew-point instruments

Modern dew point instruments differ significantly from older chilled-mirror hygrometers or slow capacitive probes. Vaisala’s DRYCAP® sensors have a highly sensitive thin-film polymer that provides:

- A fast response from wet to dry and back again

- Long-term stability and minimal recalibration needs

- High tolerance to condensing environments

- Immunity to contamination thanks to the automatic chemical purge function

- Excellent accuracy with very small hysteresis

- Fast response time with minimal drift

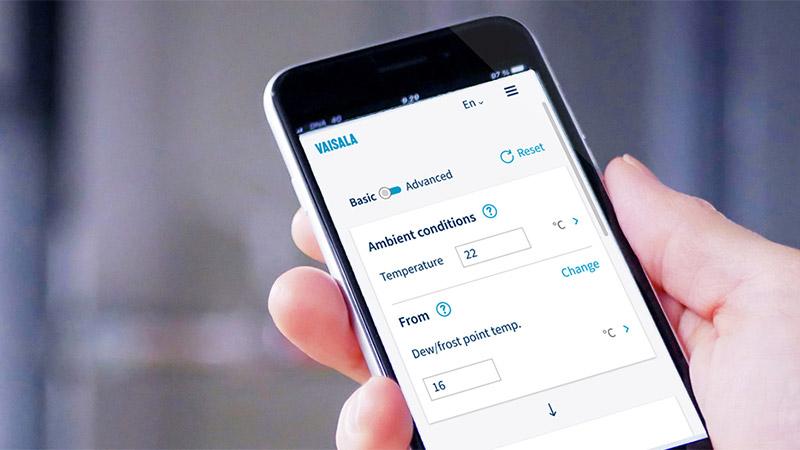

For engineers who need to convert between atmospheric dew point and pressure dew point or make other complex humidity calculations or conversions, Vaisala offers a free and easy-to-use humidity calculator.

Want to find out more about compressed air and dew point measurement? Download the Compressed Air eGuide or watch The essentials with compressed air dew point webinar.

Practical checklist for dew point measurements

✔ Choose the right places to measure, for example post-dryer and point-of-use

✔ Measure at the right process pressure, or correct properly

✔ Use stainless steel sampling lines and cells

✔ Ensure leak-tight fittings

✔ Maintain a slight, steady airflow across the sensor

✔ Avoid dead legs and purge sampling lines before measuring

✔ Keep sampling lines above dew point – use heat tracing if needed

✔ Decide when spot checking is enough and when continuous monitoring is essential

Juhani Lehto has over ten years of experience in industrial measurements and sensor technology. He holds a Master of Science degree in Technology from the Aalto University of Espoo, Finland.

Vaisala humidity calculator

Relative humidity, absolute humidity, wet-bulb temperature, enthalpy, water concentration, and many more. Humidity calculations and conversions made easy.