Why Most GxP Cleanroom Projects Fail Before Construction Starts

Most cleanroom projects don’t fail because of bad equipment, poor construction, or unexpected regulatory changes. They fail because the foundational decisions—requirements, validation strategy, and monitoring approach—are made too late, or in isolation.

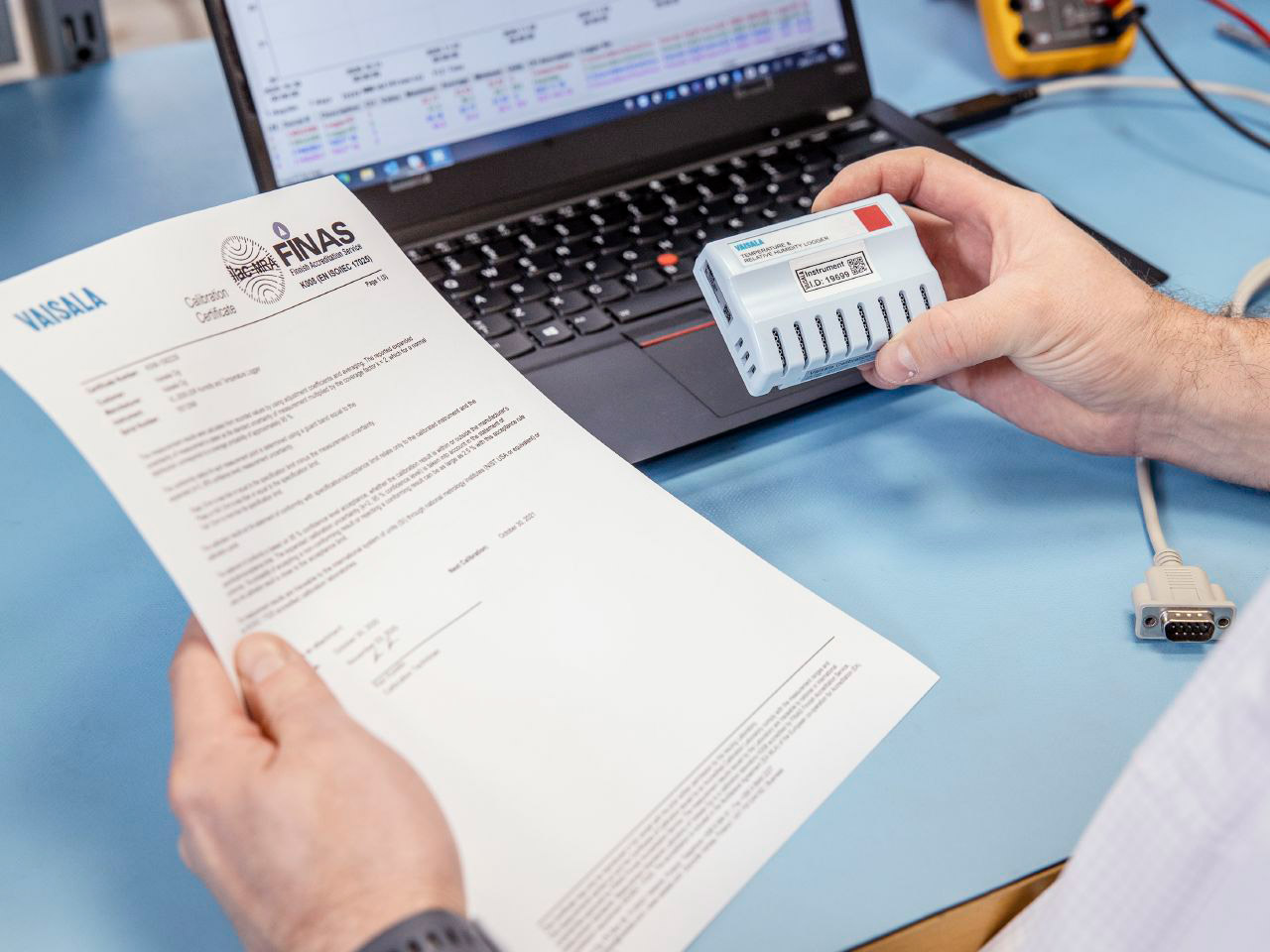

This blog introduces the same real-world design, validation, and monitoring issues discussed in our upcoming webinar, The Blueprint for GxP Cleanroom Success: Design, Compliance, Monitoring, & Real-World Application. The session brings together Blake Hodess, CEO of Hodess Cleanrooms, and Paul Daniel, Senior GxP Regulatory Expert at Vaisala.

Together, they explain—using practical examples from decades of projects—why cleanrooms that technically meet specifications still struggle in operation, during audits, or over time.

“Most customers don’t want to bring validation in early,” Hodess says. “I don’t know why—but it’s a mistake.”

From Hodess’ perspective, this hesitation shows up immediately in project documentation. He has built more than 2,000 cleanrooms over four decades, and the pattern is familiar. “We usually get an ERS and a Basis of Design—and they’re not consistent.”

That disconnect between what a customer believes the cleanroom needs to do and what the design actually supports quietly sets projects on the wrong trajectory. For Hodess, a cleanroom is never the end goal—it’s a tool in a larger manufacturing process.

“Every cleanroom has a goal. Whether it’s making a semiconductor chip, a vaccine, or doing cell therapy—we need to understand that up front. Otherwise, you’re just building a room, not a solution.”

Paul Daniel sees the same issue from the compliance side, often much later—when problems are harder and more expensive to fix.

“Validation is the face of customer quality in the process,” Daniel explains. “Our job is to make sure the requirements are being met—not just at the end, but all the way through.”

Delaying validation doesn’t just create documentation challenges. It creates risk that cannot be tested away.

“You can’t test something into compliance,” Daniel says. “By the time you’re testing at the end, it’s too late to fix fundamental design mistakes.”

This early misalignment—between design intent, operational reality, and compliance expectations—is where many GxP cleanroom projects begin to unravel, even if construction and commissioning appear successful on paper.

The Real Risk Isn’t the Cleanroom — It’s Late Alignment

By the time a cleanroom is under construction, most of the high-impact decisions have already been made. Requirements are locked. Airflows are set. Monitoring locations are hard to change. Validation strategies are either embedded—or bolted on.

That’s why both Blake Hodess and Paul Daniel return to the same theme throughout their work: cleanroom success is determined early, often before anyone thinks there’s anything to fix.

“If our customers could make product in a tent, they would,” Hodess says. “The cleanroom exists to reduce risk.”

That risk isn’t theoretical. It shows up as pressure cascades that don’t behave as designed, monitoring systems that can’t resolve meaningful excursions, audits that surface data integrity gaps, and deviations that consume time, money, and confidence.

Daniel sees the downstream impact most clearly during inspections.“Failures in life sciences don’t just cost money,” he says. “They delay medicine. In some cases, they mean patients don’t get what they need.”

The solution isn’t more testing at the end or tighter controls layered on later. It’s earlier alignment—between user requirements, design intent, validation strategy, and monitoring architecture—so the cleanroom works as a system, not a collection of compliant parts.

Go Deeper in the Live Discussion

This article highlights only part of the real-world insight shared by Hodess and Daniel. In the full webinar, they expand on these topics with concrete examples, lessons learned, and practical guidance you can apply to current or upcoming projects.

In the webinar, you’ll hear more about:

• How early validation involvement prevents expensive rework and requalification

• Where monitoring points should be placed to reflect operational reality—not just certification

• Why pressure control often presents greater risk than particles or temperature

• How to design and monitor cleanrooms that remain compliant as processes evolve

If you’re involved in designing, expanding, qualifying, or operating GxP cleanrooms—and want fewer surprises later—this conversation will give you the context that’s hardest to recover once a project is underway.

Who will get value from this webinar?

- Validation, QA, facilities, engineering leads

- People who carry the ERS/BOD burden

- Anyone dealing with late-stage deviations or audits

- Cleanroom professionals seeking proven strategies

Add new comment