KOH Scrubbing of Acidic Gas

Introduction

The treatment of acidic gas emissions from industrial processes is important as these emissions cause serious problems for the environment.

The corrosive acidic gases can have a devastating effect on buildings, vehicles or plant. Moreover, when in contact with human skin they can be harmful. That is why industrial enterprises take seriously the removal of acidic gases.

Application

One of the most common industrial emissions is hydrofluoric acid (HF). HF alkylation units generate gas which need to be neutralized prior to their burning in the flare. The presence of HF can create high corrosion rates in flare stacks, moreover, any release of HF into the air must be eliminated. It is primarily due to safety reasons that HF removal must be carried out.

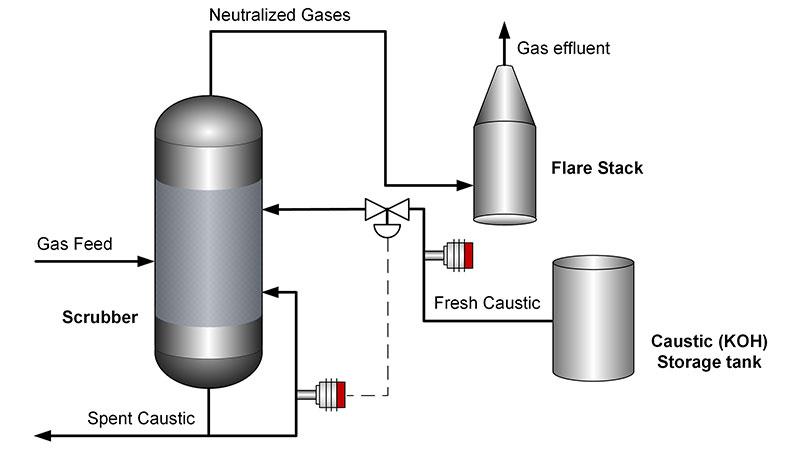

Wet scrubbing is considered one of the most common and effective ways to capture acidic gases. In the scrubber, hydrofluoric acid is removed from the gas by reacting it with a caustic solution, for example, potassium hydroxide (KOH). KOH forms a strongly alkaline aqueous solution which acts as a reactive agent neutralizing the acids. The product of the chemical reaction is potassium fluoride (KF) which is very soluble in water. After the gas has been neutralized, it can proceed to burning in the flare stack.

Typical end products

- Neutralized gas ready for flaring

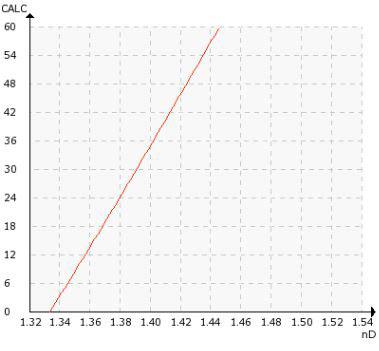

Chemical curve: Potassium hydroxide R.I. per Conc% b.w. at Ref. Temp. of 20˚C

Instrumentation and installation

Vaisala Polaris™ PR53GP Process Refractometer is used to control the make-up solution of KOH. The refractometer is installed in two locations: in the fresh KOH feed, and in the spent KOH line. The refractometer’s signal is used to control the addition of fresh KOH when the concentration of alkali drops below the optimal level. The in-line measurement ensures complete acid neutralization, and that no HF acid enters the flare.

The refractometer provides reliable measurements for safety and proper operation. The instrument’s digital sensor does not drift, is not affected by bubbles or suspended oils, thus, ensuring a stable measurement. Moreover, the refractometer provides truely digital and accurate measurement. The in-line sensor eliminates the need for sampling and laboratory analyses and replaces them with realtime data.

Vaisala Polaris™ PR53GP Process Refractometer

Description

The Vaisala Polaris PR53GP Process Refractometer is a heavy-duty instrument with non-weld body construction for diverse applications. The PR53GP can be installed directly into a tank or large pipelines, using either a standard ANSI, DIN or JIS flange connection, or clamp connection.

User Interface

Vaisala Polaris process refractometers are compatible with the Indigo platform, offering plug-and-play connectivity, user-friendly interfaces and service and configuration tools. The Indigo520 transmitter adds a physical user interface, data logging, advanced diagnostics, automatic wash control, and access to measurement settings and parameters.

Measurement range

Refractive Index (nD) 1.3200 – 1.5300, corresponding to 0-100 % by weight.