Humidity measurements in vaporized hydrogen peroxide bio-decontamination applications

vH2O2 has many advantages when compared to other commonly used sterilization agents, such as chlorine dioxide, formaldehydes, and ethylene oxide. It can be used in low temperatures and is compatible with a wide variety of materials. With the help of precise decontamination cycle control, vH2O2 can destroy the full spectrum of biological contaminants due to its ability to oxidize DNA, proteins, and membrane lipids. Another advantage of hydrogen peroxide (H2O2) is that it decomposes into water (H2O) and oxygen (O2):

2H2O2 2H2O+O2

Once a bio-decontamination aeration phase is complete, there are no toxic compounds left in the decontamination area and surfaces are left free from chemical residue.

A typical vH2O2 bio-decontamination cycle

The decontamination efficacy of vH2O2 is dependent on various factors, such as vaporized H2O2 concentration, exposure time, gas circulation, as well as the type of organisms being neutralized. Once all qualification steps have been performed and the bio-decontamination cycle has been validated, vH2O2 bio-decontamination can be repeated with satisfactory results.

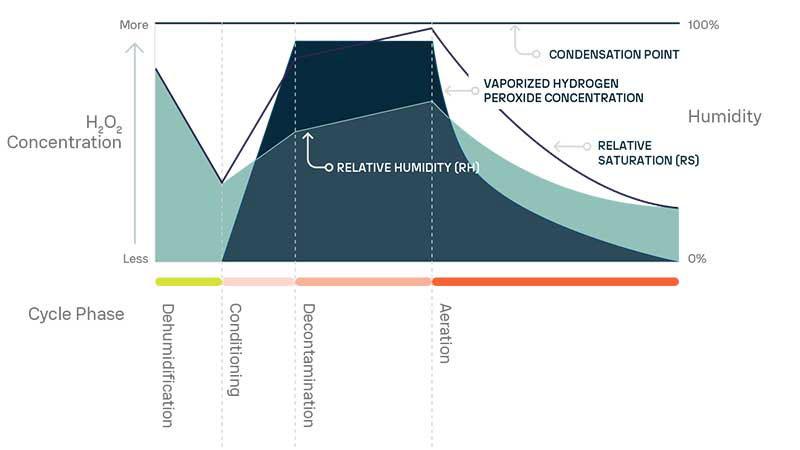

Bio-decontamination can be divided into four separate steps, each of which must be carefully controlled and monitored:

- DEHUMIDIFICATION PHASE The area under decontamination needs to be dehumidified prior to the conditioning phase because hydrogen peroxide vapor will be injected into the environment with water vapor. Failure to dehumidify may lead to undesired condensation.

- CONDITIONING PHASE This phase achieves correct conditions for decontamination and vH2O2 is injected into the environment.

- BIO-DECONTAMINATION PHASE Target values depend on the application, for example: H2O2 300–1200 ppm, humidity 50–100%. Surfaces and microorganisms are exposed to lethal concentrations of hydrogen peroxide vapor for a sufficient exposure time.

- AERATION PHASE The H2O2 is typically catalyzed into water vapor and oxygen with the help of a catalytic converter.

Relative humidity, relative saturation, and vH2O₂ concentration

Water (H2O) and hydrogen peroxide (H2O2) have similar molecular structures and both affect the humidity and saturation point of the air. Relative humidity (RH) by definition indicates only the level of water vapor in the air relative to the temperature. In air rich in hydrogen peroxide vapor, condensation will occur before 100% relative humidity.

The combination of water vapor and hydrogen peroxide vapor determines the relative saturation (RS). Relative saturation is dependent on the concentration of water and hydrogen peroxide vapor, as well as the temperature of the air. The higher the temperature, the more water and hydrogen peroxide vapor the air can hold. The lower the humidity level, the more H2O and H2O2 molecules can be added before condensation.

Standard relative humidity sensors are not recommended in vaporized H2O2 conditions because they lack a protective catalytic layer to break down the hydrogen peroxide molecules. When a humidity sensor is exposed to harmful concentrations of hydrogen peroxide it is likely to drift out of accuracy.

The amount of sensor drift will depend on the H2O2 concentration and exposure time. Since humidity sensors are designed for water vapor, hydrogen peroxide vapor will cause a stronger response in the sensor. This means that relative saturation calculated with measurements from normal humidity sensors may cause greater measurement error, especially in higher vH2O2 concentrations.

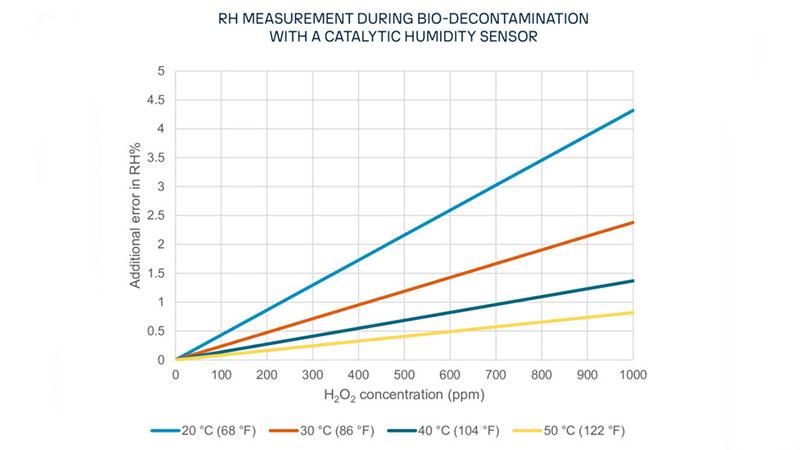

Alternatively, a humidity sensor with a catalytic layer can be used. The catalytic layer provides additional protection for the sensor by decomposing the harmful vH2O2. As a result, the sensor can only measure a relative humidity level, leaving the relative saturation level unknown. It is also worth mentioning that vH2O2 can cause additional measurement errors during bio-decontamination.

Some of the catalyzed humidity will still be measured in the sensor, creating a small positive error. The magnitude of this error is somewhat uncontrollable due to factors like vapor injection, flow speed, filters, and temperature. The sensor error caused by vH2O2 can be estimated by assuming that all the converted vH2O2 is being measured in the sensor.

For example, the maximum error influence of the catalytic filter is about +1 %RH at 300 ppm vH2O2, or +3 %RH at 900 ppm vH2O2 (at 23°C).

A humidity sensor with a catalytic layer is a natural choice in applications where humidity measurement is not necessarily needed to control the actual bio-decontamination process, but is instead used for controlling humidity conditions between cleaning cycles.

In addition to these humidity sensor features (non-catalytic and catalytic), there is an alternative solution that combines both technologies with added value. Vaisala’s PEROXCAP® technology contains both types of humidity sensors. This combination of humidity sensors, one with and one without a catalytic layer, overcomes the limitations of individual sensors.

Thus, PEROXCAP® sensors contained in Vaisala's HPP270 series probes are able to accurately measure both relative humidity and saturation as well as vH2O2 concentration.

Chemical purge for improved stability

Sensor drift caused by vH2O2 depends on various factors: H2O2 concentration, exposure time, amount of water vapor, and air temperature. For infrequent exposure, the maximum recommended vH2O2 condition for a catalytic sensor without chemical purge or heating is 400 ppm in non-condensing environments. In this case, the recommended total exposure time is 100 hours between sensor calibrations. If a higher concentration of vH2O2 is required, or if frequent decontamination cycles are expected, then a sensor with the chemical purge feature is recommended.

The HPP270 series probes include heating and chemical purge as standard features. These features make the probes an ideal solution for vH2O2 biodecontamination applications due to the high accuracy of the dual-sensor PEROXCAP® technology. Chemical purge is available as an option on several Vaisala humidity products such as Indigo series transmitters, HMM170 humidity module, and HMP smart probes.

A humidity sensor with a catalytic layer benefits from this feature because the periodic heating also improves catalytic layer stability.

If the bio-decontamination process target is to reach a subvisible condensation state, it is recommended that the probe be equipped with a composite sensor for the sensor heating cycle. The HPP270 series probes and humidity probes with chemical purge are suitable for both types of processes: non-condensing and condensing vH2O2 biodecontamination.

Recommendation for:

Monitoring bio-decontamination processes: The HPP272 probe provides a reliable way to measure relative saturation, relative humidity and hydrogen peroxide concentration during bio-decontamination.

Humidity measurement between cleaning cycles: The HPP272 with PEROXCAP® sensor, or a humidity measurement with a catalytic HUMICAP® sensor and a purge functionality, offers the best protection against the exposure of hydrogen peroxide and best performance in measuring relative humidity between bio-decontamination processes.

Summary

Choosing the right measurement method for a vH2O2 application depends on the use case. It might be enough to measure only relative humidity during dehumidification or between the cleaning cycles, relying on the stability of vapor generation equipment and other process factors. In some applications, vH2O2 control and monitoring are required. The following table compares relative humidity sensors (HUMICAP®), relative humidity sensors with a catalytic layer (CATALYTIC HUMICAP®), and the combination of these two sensors in a single probe (PEROXCAP®).

Comparison of HUMICAP® sensors, Catalytic HUMICAP® sensors, and PEROXCAP® sensors

| HUMICAP® | CATALYTIC HUMICAP® | PEROXCAP® | |

| Description | Designed to measure RH in multiple applications. | Designed to measure RH in an environment where vH2O2 is used. | Designed to measure RH and vH2O2 ppm. |

| Relative humidity (RH%) measurement during normal operation | Not recommended. Accurate, but not ideal for vH2O2 biodecontamination cycles. | Accurate relative humidity value. | Accurate relative humidity value. |

| Relative humidity (RH%) measurement during biodecontamination | Not accurate. vH2O2 may cause sensor drift. | Accurate, but extra H2O from catalytic layer can cause additional error. | Accurate relative humidity value. |

| Relative saturation (RS%) measurement during biodecontamination | Not recommended. RH reading is higher than the actual saturation level. | Not recommended. H2O2 is being catalyzed, leaving only H2O to be measured. | Accurate relative saturation value. |

| H2O2 vapor measurement during biodecontamination | Not available. | Not available. | Recommended. H2O2 vapor ppm is calculated with Vaisala’s proprietary algorithm. |

| Long term durability | Condensing vH2O2 environment will cause excessive drift. | Tolerates vH2O2 in condensing environments. | Tolerates vH2O2 in condensing environments. |

| Sensor warming and chemical purge | Optional sensor purge offers extra protection against condensation. | Optional sensor purge offers extra protection against condensation. | Standard features in PEROXCAP® . |

| Recommended Products |

|

|

|