Gelatine Evaporation

Introduction

Collagen is the main organic component of bone and skin in mammals. Acid and liming process production methods are used to produce gelatine, which is a purified protein derived from the selective hydrolysis of collagen.

Gelatine is an organic, colloidal protein substance, whose principal value depends on its coagulative, protective and adhesive powers. Gelatines swell in cold water but are insoluble in it. They dissolve in hot water to produce very viscous solutions.

Gelatines are manufactured from bones and hides, and are used in different industries: photographic, pharmaceutical and food industries.

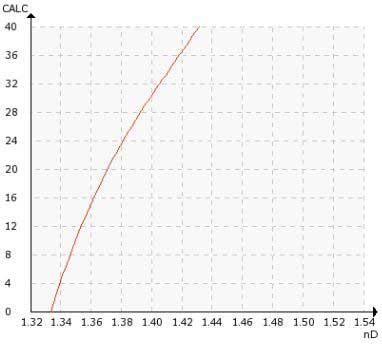

Chemical curve: Gelatine R.I.per Conc. % b.w. at Ref. Temp. of 20˚C

Application

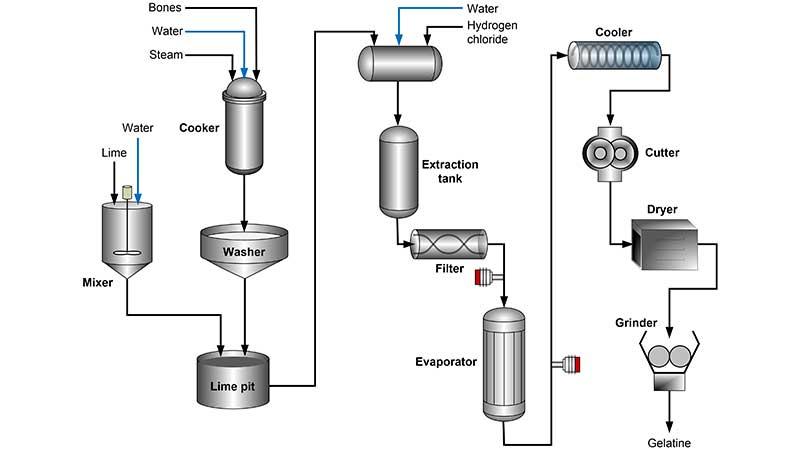

The acid process method consists of placing the bones or skins in a vat containing a dilute solution of acid for a determined period. The solution is then washed in cold water, which reduces the pH to approximately pH 4.

The liming process method consists of placing the bones or hides into liming pits with lime slurry. At the end of this operation, the raw material is washed to remove residual lime and the hydrolysed organic impurities.

The next stage is the most important in providing different qualities of gelatine. At this point, the gelatine extract with a concentration of around 5 % is filtered, deionised in an ion-exchanger and concentrated in multiple-effect vacuum evaporators. A 15 % solution is obtained and filtered through cellulose filter-cakes and evaporated up to 30-40 %. The concentrated solution is then sterilized, cooled and extruded to gelatine sheets. The final gelatine product is dried in a tunnel dryer.

Typical end products of gelatine:

- gelling agent in food

- pharmaceuticals

- photography

- cosmetics

Instrumentation and installation

Vaisala Polaris™ PR53G Process Refractometer is used at the most important step, where the quality of the gelatine and the efficiency of subsequent operations are defined. The refractometer is installed between filtration and the evaporation plant, directly in the pipeline after the circulation pump.

The typical measurement ranges for gelatine production are 0-15 % and 0-40 % before and after evaporation, respectively. The process temperature of about 60 °C (140 °F). Steam cleaning is recommended for concentrations above 5 %.

Vaisala Polaris process refractometers

The Vaisala Polaris PR53GP Process Refractometer (pictured) is a heavy-duty instrument with nonweld body construction for diverse applications. The optional flange-mounted pipe flow cell installation accessory allows flange-mounted installation in a wide variety of pipe sizes.

The Polaris PR53GC Compact Process Refractometer is suitable for a wide range of industrial applications. Special alloy material are available for demanding environments. Convenient installation with Type L coupling. A selection of flow cells available.

User Interface

Vaisala Indigo520 transmitter integrates with Polaris PR53 process refractometers providing an expanded feature set, including a physical display for real-time measurement data and advanced diagnostics, more output options, data logging, and automated prism wash control. This combination enables efficient process monitoring and easy access to diagnostic information.

Measurement range

Refractive Index (nD) 1.3200 – 1.5300, corresponding to 0-100 % by weight.