Why humidity measurements matter in semiconductor manufacturing

In semiconductor manufacturing nothing matters more than accuracy. From microchip fabrication to the final assembly of integrated circuits, every step in the process requires precise measurements for high-quality, repeatable results. One of the most critical parameters to measure is humidity, as maintaining exactly the right moisture levels is crucial for optimal equipment performance and end-product quality.

Maintaining the perfect environment

When you are manufacturing in nanoscale, even slight inconsistencies can lead to catastrophic results. Environmental conditions need to be monitored and maintained with extreme precision as semiconductor components like chips and printed circuit boards are extremely vulnerable to moisture. Water is, in fact, the most significant contaminant in semiconductor manufacturing, with estimates indicating that non-optimal moisture conditions account for as much as 25% of lost revenue.

Excessive humidity can result in corrosion, electrical shorts, poor component quality, and a higher failure rate. Humidity that is too low can lead to static electricity build up, which can damage semiconductor surfaces and significantly reduce production yields. Accurate humidity control is therefore critical, making reliable sensors essential – a smart investment with an impact that’s much greater than their size or cost. High-quality sensors and transmitters ensure that both equipment and the environment remain within optimal ranges for semiconductor fabrication.

Measurement solutions for semiconductor manufacturing processes

Let’s look at some semiconductor manufacturing processes where humidity management is essential – and the solutions that can help.

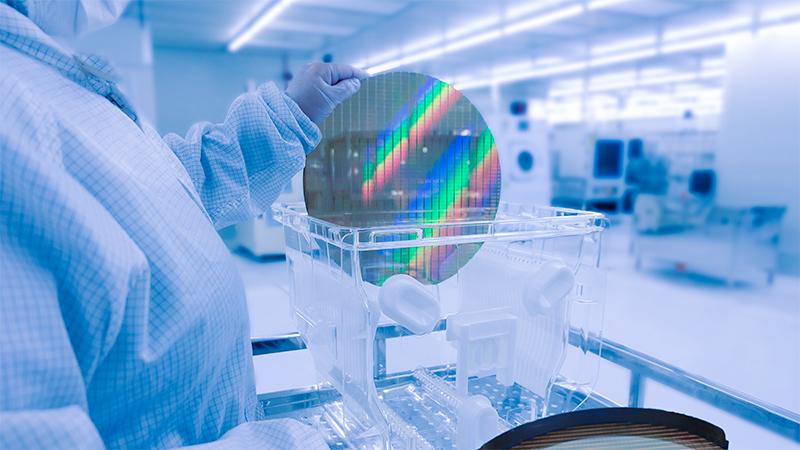

Silicon wafer polishing and cleaning

Silicon wafer polishing and cleaning is a key step in semiconductor manufacturing. The process involves high humidity and harsh chemicals that can cause sensor drift, making accurate measurement even more of a challenge.

Probes for this type of environment need to withstand both high humidity levels and exposure to harsh chemicals. One excellent solution is the Compact Temperature and Humidity Probe HMP9, which is a compact device with a very fast response time. It can withstand high humidity levels and also has a chemical purge function for post-contamination sensor cleaning. For machine or tooling manufacturers Vaisala also offers modular humidity and temperature products such as the Relative Humidity and Temperature Module HMM170, which can be integrated into end products.

Wafer steppers, coating, and developing machines

Wafer steppers that coat and develop silicon wafers are laser-based so even the smallest ambient variations can significantly affect process quality. The ambient pressure, relative humidity, and temperature all influence optical behavior and lens focus, and this must be monitored and compensated for in real time. When working in nanoscale, precisely measuring and monitoring these parameters becomes even more critical.

One excellent solution for these machines is the modular Vaisala Indigo520, which offers pressure as an optional measurement parameter. The humidity and temperature probe HMP3 is compatible with the Indigo520 and features a structure that allows the sensor to be replaced in the field without tools, making it ideal for cleanroom environments. For processes that need to monitor other parameters, such as CO2 and dew point, a range of other probes are available. Whichever you choose, the probe can be connected to a central transmitter such as the Indigo520, giving you the flexibility to choose the best combination for your process.

Wafer dicing and probing machines

The wafer dicing process, where individual chips are separated from the wafer, needs accurate humidity measurement to protect both the product and the machines. Condensation can be an issue, particularly when the tape is peeled off, so dew point needs to be monitored carefully. During probing, chips are subjected to extreme temperature variations to test integrated circuit performance. This process demands precise control of dew point and humidity to prevent condensation and rust formation in the test chambers.

Vaisala offers several compact devices for monitoring and controlling these parameters. There is the DMT143 Miniature Dew Point Transmitter, which covers a wide measurement range from -70°C to +60°C for frost and dew point. Another option is the Vaisala Dew Point Transmitter DMT152, which is optimized for ultra-dry conditions and offers frost point measurements as low as –80°C with +/– 2°C accuracy. Both products feature autocalibration, ensuring very long calibration intervals, and are easy to integrate into any OEM application like semiconductor manufacturing machines or testing devices.

Process line gas quality

The cleanrooms used in semiconductor manufacturing rely on high-quality, non-reactive process gases like nitrogen and argon. Ensuring the dryness of these gases is crucial to maintain the purity of the environment and avoid potential contamination during sensitive manufacturing stages. Moisture levels need to be monitored in the process gas line to ensure an accurate measurement result. It’s best to use polished stainless steel tubes in the piping as this helps ensure accurate, contaminant-free readings.

Vaisala DRYCAP® sensors are ideal for monitoring gas dryness as they offer an extremely fast response time, saving expensive gas and protecting processes in error situations. They also feature autocalibration for superior long-term stability. The Vaisala Dew Point Transmitter DMT152 is an excellent choice for this application, offering real-time, high-quality measurements. The DMT152 should be installed directly in the gas flow to ensure a representative gas sample, using tapered threads to prevent leaks. Vaisala sampling cells are made of polished stainless steel, ensuring accurate, high-quality measurements.

The importance of humidity control

Humidity control helps to prolong the lifespan of semiconductor manufacturing equipment and maintain end-product quality. By implementing high-quality sensors and transmitters to monitor and control humidity levels throughout the production process, manufacturers can safeguard their operations against moisture-related issues, reduce costs, and maximize yield.

Contact us today to find out how our sensors could benefit you.

Solutions for semiconductor process, facility monitoring and control

Semiconductor wafer and microelectronics fabrication is a demanding process with little room for mistakes. The industry depends on high-performing monitoring and measurement instrumentation for precise chemical compositions and atmospheric conditions.