Regional CCU™: pioneering decarbonization initiative of Niterra, powered by CO2 measurement technology

IGNITE YOUR SPIRIT: The transformation of NGK SPARK PLUG CO., LTD. into Niterra Co., Ltd.

Niterra Co., Ltd. (Niterra), formerly known as NGK SPARK PLUG CO., LTD., was founded in 1936 in Nagoya City, Aichi Prefecture, Japan, where its headquarters remain today. The company’s first president, Mr. Magoemon Ezoe, promoted the use of porcelain—a Japanese specialty—for spark plugs. Building on this foundation, the company became a global leader in spark plugs for internal combustion engines. Over the years, Niterra has commercialized innovations based on ceramic materials, such as ceramic IC packages, ultrasonic transducers, automotive oxygen sensors, and electrostatic chucks, expanding its technological and business domains. Its core competencies now include ceramic material technology, a global business platform, and sensing technology.

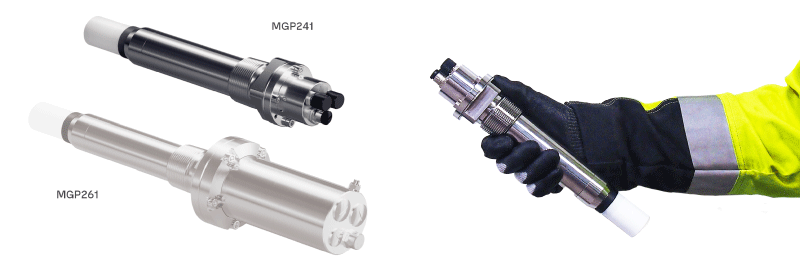

Photo 1: Multigas probe MGP261 selected for this project, enables simultaneous measurement of CO2, methane, and dew point.

In 2023, the company rebranded as the “Niterra Group” by changing its English company name and adopting the mission to become “a company brightens the entire global environment.” The company is committed to addressing global challenges and building a sustainable society. As of March 2025, Niterra operates 31 domestic and 62 international sites, employing 15,644 people. It is accelerating efforts in three key areas: “environment & energy,” “mobility,” and “semiconductors.”

“REGIONAL CCU™”: What are the measurement instrument requirements for its development?

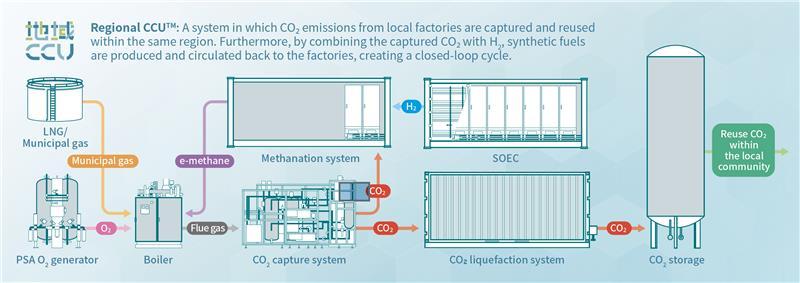

As part of its “environment & energy” strategy, Niterra is pursuing “Regional CCU™ *”—a vision to reduce a region’s CO2 emissions to near zero. CO2 from factories is captured via various technologies and reused locally. Hydrogen is generated through solid oxide electrolysis (SOEC), then methanated into e-methane fuel used in factories. This unique carbon recycling approach leverages regional industrial features to address social and environmental issues. The initiative is advancing through collaboration with local firms and municipalities in Gamagori City, Aichi Prefecture.

*CCU: Carbon dioxide Capture Utilization

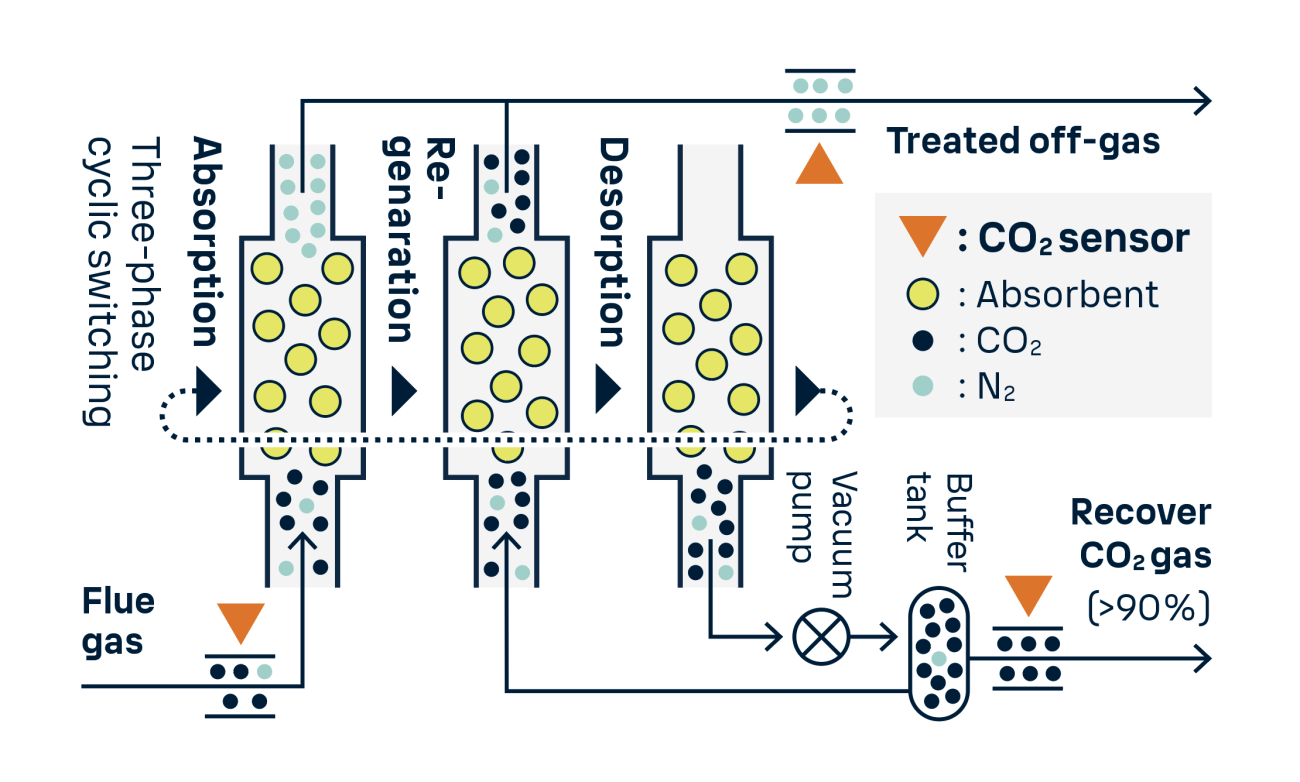

Niterra is using Vaisala’s CO2 measurement instruments, including the MGP series, in developing its CO2 capture system—one of the cornerstones of “Regional CCU™.” Targeting small- to mid-scale sources like industrial furnaces and boilers, the system employs VPSA (Vacuum Pressure Swing Adsorption), processing 64 Nm of exhaust gas per hour and recovering over 90% of the CO2. Development began in October 2021 and is now in the commercial design phase, with a market launch planned for 2027.

“Precise CO2 measurement is essential,” explains Shota Takahashi, Senior Engineer, Carbon Recycling Development Dept., Energy Business Div. “Earlier options had challenges like the need to dry sample gas and long-term stability, requiring large, complex, and costly support systems. Vaisala’s MGP261 helped us solve these key issues.”

The MGP261, a compact multigas probe using Vaisala’s proprietary NDIR CARBOCAP® sensor, enables in-line measurement of CO2, methane, and dew point. Key features include:

- Supports simultaneous 0–100% CO2 and

methane measurement with dew point monitoring in the -10 to +60°C range - True in-line installation

- No gas sampling or drying required

- Virtually maintenance-free; no daily calibration

- MEMS Microglow infrared light source, 15+

year lifespan - Tuneable optical filer without moving parts

- Long-term stability with auto-calibration

- Certified for use in explosive atmospheres

"In the development of the CO2 capture system, the CO2 measurement instruments we initially considered had several issues, particularly with dehumidification and long-term stability. The only available measurement methods that could resolve these challenges required relatively complex and large-scale auxiliary equipment, along with significant costs. With Vaisala’s MGP261, we were able to overcome those core challenges."

Shota Takahashi Senior Engineer, Carbon Recycling Development Dept., Energy Business Div.

“We need raw, continuous CO2 data to monitor what happens inside the system—when and where. Real-time measurements without gas pretreatment are crucial. MGP261 offers a simple solution. Its reliability, low-maintenance and easy-to-use design reduce costs and make it easier to expand measurement points,” Takahashi notes. “It also enables optimization by directly linking real-time CO2 values to system controls.”

What should the size and mechanism of the absorption towers, buffer tanks, and overall system be? To determine the most rational design for commercial deployment, accurate, continuous gas data is vital at key points in the test system. The MGP261 meets these requirements and also supports development of the methanation unit, thanks to its methane measurement capability.

FROM DEVELOPMENT TO DEPLOYMENT: Measurement instruments supporting realization

“Our vision is to build a CO2 capture system that’s compact and cost-effective enough to be used not only by large firms but also by smaller businesses—true to our ‘Regional CCU’ vision,” says Masahiro Kajitani, General Manager, Carbon Recycling Development Dept., Energy Business Div.

“Assuming a future where carbon credit trading demands greater transparency, we believe that actual measured values on the output side will increasingly be required. Considering this outlook, the MGP241 — which has been simplified and offers highly accurate, long-term stable continuous measurement of raw CO2 data — will likely become an essential choice in the CO2 capture process.”

Masahiro Kajitani General Manager, Carbon Recycling Development Dept., Energy Business Div

In 2024, Vaisala introduced the MGP241, a specialized multigas probe for CO2 and dew point measurement. By excluding methane sensing and explosion-proof features, it offers a lower-cost, more compact design—perfect for measuring 90– 100% CO2 concentrations after recovery. As such, it stands out as a rare option that combines performance and usability, making continuous CO2 monitoring within the system even easier.

"Currently, GHG emissions are typically calculated using theoretical values, by multiplying fuel consumption on the input side by an emission factor. However, as carbon credit trading becomes more transparency-driven, we believe that actual measured values on the output side will increasingly be required. In the light of this outlook, the MGP241 as a simple instrument capable of continuously measuring 'raw CO2 data' with high accuracy and long-term stability, is likely to become an essential solution in the CO2 capture process," says Kajitani.

He adds that minimizing total lifecycle cost - both of CAPEX and OPEX - is critical to promoting widespread adoption of decarbonization technologies. He appreciates Vaisala’s support: “Local team work closely with the global team and are very responsive. Despite being a global company, their localized documentation and technical support are excellent.”

Alongside the MGP261 and MGP241, Niterra also uses Vaisala’s GMP series for lower-concentration CO2 and DMP series for dew point monitoring. Backed by nearly 90 years of innovation, Vaisala supports this initiative with best-in-class instruments and expert collaboration—advancing the realization of Niterra’s carbon recycling goals.

Key features of multigas probe MGP241

- Proprietary CARBOCAP® non-dispersive infrared (NDIR) sensor

- Enables simultaneous in-line measurement of CO2 and dew point

- Direct in-line installation into the process pipeline for continuous measurement

- Maintenance-free in daily operation

Photo 5: Light weight, compact probe design of MGP241.