Leading packaging film manufacturer chooses Vaisala measurement instruments for eco-friendly packaging solution

The client: Futamura UK

Vaisala provided: HMT330 and HMT360 series humidity & temperature transmitters followed by two Indigo520 transmitters and four HMP5 relative humidity & temperature probes

The challenge: To continue making packaging that doesn’t cost the Earth

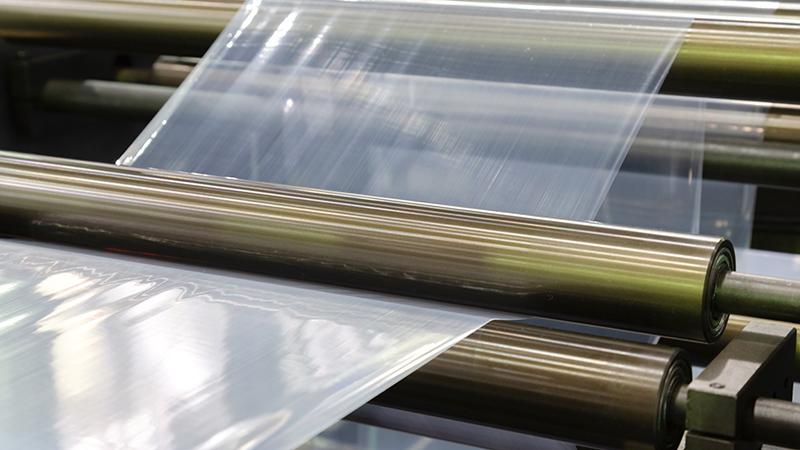

With companies worldwide looking to reduce both waste and the carbon footprint of their products, growing demand for environmentally responsible packaging has seen Futamura become the world’s largest producer of sustainable cellulose packaging films, including their leading NatureFlex™ range.

To produce such sustainable films requires precise conditions to be maintained in the production process. This makes highly accurate temperature and humidity measurement essential, particularly during the film drying process and when finished products are stored. Futamura UK uses Vaisala measurement equipment across their site, including Vaisala HUMICAP® Humidity and Temperature Transmitters HMT360 in their coating towers inside their conditioners. As the coating towers contain solvents which are highly flammable, the products used in these areas must be certified for the Ex environment. The Vaisala HMT360 transmitters, now superseded by the ATEX-certified HMT370EX, are intrinsically safe, making them ideal for use in hazardous areas like these.

Vaisala measurement instruments can also be found on Futamura UK’s casting machines, installed in the dryer ducting to measure temperature and humidity. The Vaisala HUMICAP® Humidity and Temperature Meter Series HMT330 is designed to provide highly accurate measurements in demanding industrial applications. These transmitters control a valve which increases or decreases the amount of steam that goes into the dryers, allowing the humidity to be maintained at the set point needed for the drying of each specific film type. Moisture content is a significant factor in the properties of the final film, so accurate control is essential to ensure quality and reduce waste. With the HMT330 series being an older model, Futamura wanted to future-proof their measurement instrumentation – so the company got in touch with Vaisala for advice.

The solution: Service, support, and leading technology

Vaisala’s Sales Manager Andrew Williams visited Futamura’s UK site in Wigton, Cumbria to demonstrate the benefits of switching to Indigo and discuss the options available with David Carr, Electrical Engineering Chargehand, and David Mansergh and Chris Reid, Technical Engineers.

“We explained to the Vaisala sales manager where we were using the HMT330 series instruments and he suggested we try the Indigo520 display with a Relative Humidity and Temperature Probe HMP5,” explains Carr. “We were more than happy with the suggestion. His vast product knowledge and extensive expertise in engineering and process systems was a huge benefit in the decision-making process. He also went through the calibration process and how to set the equipment up with our electrical engineers. Vaisala’s service and support have been first class – Andrew has gone above and beyond to help us.”

The Indigo520 can connect with two separate probes simultaneously and it has a clear and easy-to-navigate touchscreen display. Futamura particularly appreciates the screen size and easy-to-read graphs, as well as the ability to swap out probes for calibration. It has also helped that the HMP5 probe works in the same way mechanically as the HMT330 devices, which they are already very familiar with, and is installed with the same mechanical hardware.

"When you find products – and a company – you can trust, it makes good business sense to continue the relationship. Futamura have been using Vaisala measurement instruments for many years to help us ensure the quality of our sustainable packaging films, and we will continue to do so in future. As a plant we like to keep a site standard as it makes it easier to keep spares and to replace equipment when necessary. It’s safe to say that Vaisala is our brand of choice because of its reliability and ease of installation and use.

David Carr, Electrical Engineering Chargehand, Futamura UK

David Carr, Futamura UK

The benefits: consistently high-quality sustainable packaging film

By using Vaisala measurement instruments in their manufacturing process, Futamura enjoy the following benefits:

- Accurate control of the production process

- Consistent product quality

- Less waste

- Trusted service and support from solution experts

- The peace of mind that comes with proven and reliable solutions

About Futamura

Futamura is a Japanese-owned business with production plants in Japan, the UK, and the USA. The company employs around 2,000 people and produces high-quality packaging films, fibrous casings, non-woven fabrics, activated carbon, and phenolic laminated sheets.