Eliminating measurement drift in online DGA monitoring

A look at the benefits of Vaisala's proprietary IR reference measurement

No measurement device is safe from drift. That’s a fact. But what is it and what can you do to prevent it? This blog has the answers.

What is drift? And why should you care?

Drift is simply a technical term to describe the fact that every single measurement device — no matter how good, and no matter where on Earth — will measure differently as time passes. On day 1, you could get spectacularly accurate and reliable measurement results. The kind of results you expect. The kind of result you can trust.

But over time things will change. This holds true for all devices. Your car's odometer, a tape measure, a DGA monitor... Whichever measurement device you use, it will wear, get dirty, go dimmer, stretch, shrink... In a word, its performance will change. That's as true for high technology as it is for your eye or thumb. This means that, over time, even if the thing being measured didn't change, the results slowly will, until you can't trust the results.

Drift in dissolved gas analysis (DGA)

When you're measuring something as critical as a power transformer, drift simply can't be tolerated. If you can't trust the results, what do you base your maintenance decisions on, and what about false alarms?

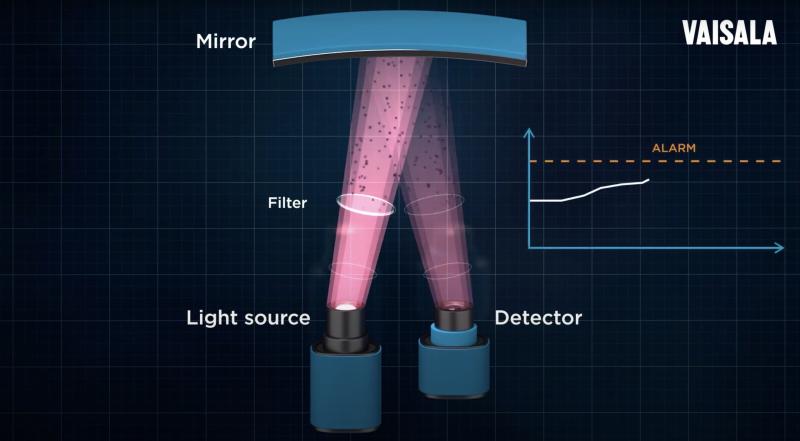

In IR-based DGA, gas measurement is specifically about measuring how much light passes through a gas sample. The more gas, the less light comes through to the sensor. In IR, drift is primarily caused by:

1. Light source aging. The older the light source, the dimmer it will get.

2. Optics contamination. Dirt, dust, oil and other materials will adhere to the optical parts, dimming the light output.

Both will cause the IR light to get dimmer — and that's the core of the problem. Dimmer light means less light will be detected, which the measurement device will interpret to mean there's more gas than there really is. That will lead to a false alarm, costing you money and trouble.

But Vaisala has developed a solution for eliminating drift.

How can Vaisala minimize drift in online DGA?

To minimize the drift effect in the first place, several common issues have been taken into consideration in designing the Optimus™ online DGA monitor. For the IR light drift specifically, the Optimus has an ultra-stable microglow light source, manufactured in our own clean room. Its lifespan has been tested to be decades, and it will stay bright for longer than conventional light sources. To eliminate light source dimming through dirt and dust, the Optimus™ has a hermetically sealed design that prevents contamination.

But even this can't completely eliminate drift.

Eliminating the effects of drift entirely – the secret ingredient of the Optimus.

Vaisala has developed a technology we call IR reference measurement. It will give stable, reliable DGA results even if drift-causing elements are present.

The Optimus measures twice on each measurement cycle. Once in a vacuum, which tells us the maximum amount of light available from the IR microglow. Then the measurement is repeated with the extracted gas. And because the maximum amount of available light is known, we can reliably measure the absorption of light in gas and completely eliminate the effects of drift. Resulting in robustly reliable DGA readings.

The end result? No matter how long you operate your Optimus, its measurement will be as reliable as the day it was first powered on. And when you can trust the measurement data, you can make better-informed decisions.

That's all there is.

Click for more about the Optimus OPT100 online DGA monitor »

Add new comment