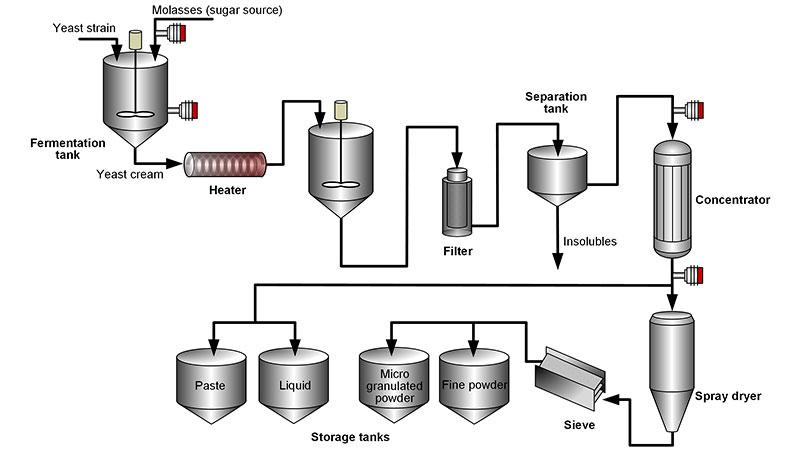

Yeast extract process

Introduction

Yeast extract is a processed product, which comprises the water-soluble components of yeast cells.

Yeast extract is used in a broad range of applications. In the food industry, it is used as food flavoring, e.g. in soups, sauces and ready meals. Yeast extract is also used as an additive, vitamin supplement, as well as nutritional source for bacterial culture media.

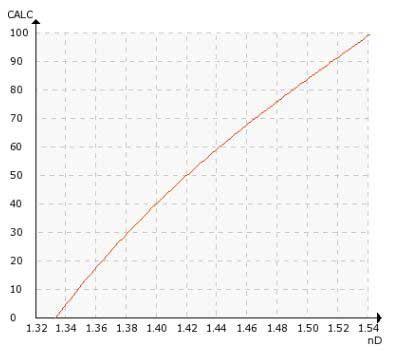

Chemical curve: R.I. per BRIX at Ref. Temp. of 20˚C

Application

Yeast extract is prepared by extracting the cell contents from baker’s or brewer’s yeast (saccharomyces cerevisiae). The process starts with the selection of the right yeast strain that meets the customer’s needs. This yeast strain is the inoculum fed into a tank where it grows at sterile conditions before it is transferred to a larger fermenter. The strain is cultivated in progressively larger vessels until it reaches the capacity of the production fermenters. During cultivation air and a sugar source, for example molasses, is added to nourish the yeast. The fermentation allows yeast to grow in an aerobic environment and at a controlled temperature (around 30 °C or 86 °F). After fermentation the residual sugar is removed, and the yeast is washed and concentrated. The product from fermentation, known as the yeast cream, undergoes a heat treatment at a moderate temperature that allows opening the cells while conserving the enzymes.

The next step is autolysis. Autolysis is the process by which a cell will digest itself through the action of its own enzymes, releasing the intracellular content. Autolysis involves the freeing of enzymes within the yeasts to break down the proteins. This step of the process is performed under mild pH and temperature. Its duration depends on the type of yeast and the extent the proteins must be broken down.

After autolysis, the insoluble part in the solution, such as yeast cell walls, is separated from the water-soluble components. Separation is done by filtration. The water-soluble part will constitute the yeast extract.

Before proceeding to packaging or spray drying, the yeast extract must be concentrated and pasteurized. In this step, water is removed from the solution to achieve a desired concentration. The final concentration must be measured continuously to ensure a high-quality product and optimal operation of the downstream equipment. The concentration for a liquid product must be 50-65 % dry solids, and for a paste yeast 70-80 % dry solids. The yeast extract can be dried to a fine powder or granulated particles by spray drying.

The final yeast extract is then packed

Typical end products of yeast extract solution

- yeast

- food ingredients

- flavorings and seasoning

- nutrients for bacterial culture media and skincare products

Instrumentation and installation

Vaisala Polaris™ PR53A Process Refractometer allows yeast extract plants to continuously monitor different stages of their process. The refractometer can be used at the initial step to control dilution of molasses and to monitor that the sugar source for cell cultivation is at the correct Brix level. This ensures that enough nutrients are supplied for cell growth and enhances the yeast cultivation process.

The refractometer can also be installed directly in the fermentation tanks to follow reaction progress and to monitor yeast content inside the vessel. The measurement by the refractometer is selective to the dissolved material in the liquid phase and is not affected by suspended solids or bubbles.

At the concentration step, the refractometer is mounted directly on the pipe bend after the concentrator or pasteurizer. The refractometer measures in-line the concentration of the yeast extract to ensure the target dry solids level is achieved. In addition, a refractometer can be installed before the evaporator or concentrator. The refractometers’ mA or Ethernet output signals can then be used not only for quality control, but also for controlling automatically the process and for optimizing energy consumption.

Typical temperature in this application is 30-60 °C (86-140 ºF), and the measurement range is 0-100 Brix. Automatic prism wash might be required in this application.

The PR-43-A is designed to meet the highest hygiene requirements. The refractometer is available with 3-A and EHEDG certifications.

Vaisala Polaris Sanitary Process Refractometers

The Vaisala Polaris PR53AC Sanitary Compact Process Refractometer (pictured) is for hygienic applications. Convenient installation directly to process lines with standard sanitary and Type N couplings, or with a sanitary flow cell. The product is also compatible with clean-in-place (CIP) and sanitation-in-place (SIP) systems.

Vaisala Polaris PR53AP Sanitary Probe Process Refractometer is for hygienic installations in large pipes, tanks, cookers, crystallizers and kettles. The long probe with common tank bottom flanges enables installation depths of up to 170 mm. The flush mount option allows installation in tanks with scrapers or mixers. The product is also compatible with clean-in-place (CIP) and sanitation-in-place (SIP) systems.

User Interface

Vaisala Polaris process refractometers are compatible with the Indigo platform, offering plug-and-play connectivity, user-friendly interfaces and service and configuration tools. The Indigo520 transmitter adds a physical user interface, data logging, advanced diagnostics, automatic wash control, and access to measurement settings and parameters.

Measurement range

Refractive Index (nD) 1.3200 – 1.5300, corresponding to 0-100 Brix.