Temperature Mapping with the viewLinc Monitoring System

Mapping and monitoring are very similar processes. In both cases, environmental data is collected at regular intervals from field-deployed data loggers. The primary difference is that in monitoring, the data loggers are permanently deployed in a set location and the data can be viewed live. In a temperature mapping qualification, the data loggers are typically deployed for short time periods in locations that change from study to study. Because of this similarity, temperature mapping qualifications can easily be performed with viewLinc.

Vaisala Data Loggers for Mapping

The Vaisala DL-Series data loggers have been used for mapping studies in regulated applications all over the world. These data loggers are valued for their 10-year battery, large memory capacity, and high-accuracy sensors. In a typical mapping with DL-Series loggers, Vaisala vLog software is used to configure the loggers and download the data when the study is complete. The viewLinc monitoring software can more easily perform the same functions for configuring loggers, downloading data, and reporting results.

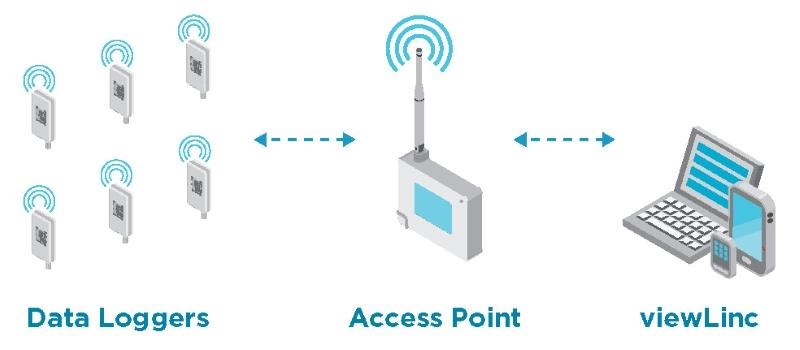

Our new wireless RFL-Series data loggers are as reliable as the DLSeries loggers, but have features that make them better suited to mapping, including the Vaisala VaiNet wireless communication protocol and smart probes on the data loggers.

VaiNet is Vaisala's proprietary wireless technology based on LoRa® wireless radio frequency technology. As the devices in VaiNet, the RFL-Series data loggers can reliably transmit data over 100 meters, even in complex manufacturing environments. In our field experience with the RFL-Series data loggers, lineof-sight ranges exceed one kilometer. Live mapping data can be viewed from any environment – from a freezer room to a large ambient warehouse. The practical importance of this feature is efficiency; data is transferred live in real-time, and it is not necessary to wait to know if study data will meet acceptance criteria. You will never again collect your data loggers only to learn that the study failed.

The RFL-Series data loggers use smart probes that are separate measurement devices with calibration data stored in on-board memory (e.g. Vaisala HMP115). The smart probe also performs local A/D signal conversion. These functions mean that only the smart probe needs to be calibrated, not the data logger. After a mapping study, the smart probes can be removed for post-study calibration verification and the logger body can be equipped with a calibrated smart probe to be immediately deployed in the next mapping study.

Customers who perform highvolume mapping studies can do more studies with the RFL because the data logger units never need to be taken out of service for poststudy calibration verification.

The RFL-Series data loggers are also equipped with other features that simplify mapping studies:

- Data is synchronized automatically with NTP (Network Time Protocol)

- Fixed 1-minute sample rate

- 30 days of on-board memory in case of Access Point disconnection

- LCD display on data loggers for verification of “ON” status and to indicate exceeded threshold limits

- Continuous data recording once “ON”

- 18-month battery life with two standard AA alkaline batteries

- Wide temperature measurement range depending on probe:

- -20°C to +80°C with a fixed probe

- -196°C to +90°C with a remote probe

Mapping with viewLinc Enterprise Server Software

viewLinc is an enterprise-level continuous monitoring system software designed for GxPregulated industries. The software can be used for temperature mapping with only a few procedural steps to account for the fact that mapping studies are a noncontinuous operation.

The viewLinc software is designed to accommodate and repair interrupted network connections. If connection is temporarily lost, monitoring data is stored locally in the data loggers. When network connection is re-established, the data is downloaded from the data loggers to the viewLinc database in a process we call “backfill”. When using viewLinc to download data from a mapping logger, you take advantage of the backfill process. When a data logger is connected to viewLinc after a mapping study, the software regards the data logger as if it was temporarily disconnected and automatically begins the download.

Because of the long range of the VaiNet wireless signal, you can leave the RFL-Series data loggers connected while performing a mapping study. This allows you to view live data throughout the study. Because viewLinc is a monitoring system, it can instantly notify you if your mapping data fails to meet acceptance criteria, preventing time lost to failed studies.

viewLinc Mapping Procedure

- Install and validate viewLinc using its template IQOQ Protocol. This step is performed once upon software installation.

- Install the data loggers on viewLinc. Again, this is performed only once so that the software will always recognize these data loggers as valid devices.

- Create “Locations” for your mapping sensors in viewLinc. Link the locations to the data loggers with a simple dragand-drop action. In viewLinc, a “Location” is a virtual data storage location that will hold the information from the data logger you link to it. Linking the data loggers to different locations for each study keeps the mapping data for each study separate.

- Set Acceptance Criteria for each Location using a Threshold Alarm Template. In a typical mapping study, only one template is needed. The template can then be easily applied to all mapping Locations. The Acceptance Criteria can include temperature limits as well as excursion duration.

- Clear and Synchronize Data Loggers, if applicable.

- Perform pre-study calibration verification of the data loggers (Note: Many customers find Vaisala data loggers reliable enough that they skip this step and rely on the annual factory calibration instead.)

- Deploy data loggers for your mapping study. viewLinc Mapping Procedure

- You will be able to view the mapping data live and receive notifications if the data is out of specification (if using RFLSeries data loggers). This can be used to determine when equilibrium is attained before starting the study.

- Initiate the study.

- Once the study is complete, collect the data loggers.

- Download Data, if applicable.

- Generate “Alarm History” and “Location History Reports” for each Location.

- Perform post-study calibration verification of data loggers.

Other Considerations

- Acceptance criteria MUST be set before the study is performed. Use alarm thresholds to create the acceptance criteria. Note that The RFL100 Wireless Temperature Data Logger uses VaiNet proprietary wireless technology to connect to viewLinc. Shown with probe extension cable. RFL-Series data loggers come in temperature only or temperature and humidity models. the viewLinc software does not allow alarm thresholds to be created retroactively.

- Two reports may be required to view the necessary data:

- The “Alarm History Report” identifies any excursions that violated the Acceptance Criteria.

- The “Location History Report” provides both raw and statistical data, including maximums and minimums for each Location.

- For more advanced data analysis, export data to a .tsv file for import to a spreadsheet.

- viewLinc was designed for enterprise, multi-site continuous monitoring. Because mapping studies are a simpler process, there are many features in viewLinc that are not used in mapping studies.

Vaisala Data Loggers Used for Mapping Studies

- DL-Series

- Humidity and Temperature

- Temperature Only

- RFL-Series

- Humidity and Temperature

- Temperature Only

cable. RFL-Series data loggers come in temperature only or temperature and humidity models.

Conclusion

Vaisala’s viewLinc monitoring software is a robust and reliable system designed for GxP applications. While viewLinc was designed for continuous monitoring, the software can easily be used to manage temperature mapping studies. If you already have viewLinc for monitoring, using it for mapping is a costeffective and efficient alternative to thermocouple-based equipment, bulky data acquisition systems, and less robust data loggers. It can easily be used to map any typical GxP storage environment, including stability chambers, refrigerators, freezers, incubators, warehouses, ambient environments and other demanding environments.

When using the viewLinc continuous monitoring software for mapping studies, you leverage Vaisala’s wide range of easily deployed data loggers, high accuracy sensors, user friendly software, and where VaiNet is used, simple and reliable wireless connectivity. All of these features allow high confidence in mapping study results.