Starch sweeteners evaporation

Introduction

Evaporation is used at different stages of the process, for example, for concentration and recovery of sweetener from sweet water, or for concentrating the syrup to the final product specifications.

Evaporation is one of the largest heat consumption operations in the starch industry. This explains why one of the major activities in the industry is the development of methods for optimizing evaporation and reducing energy consumption.

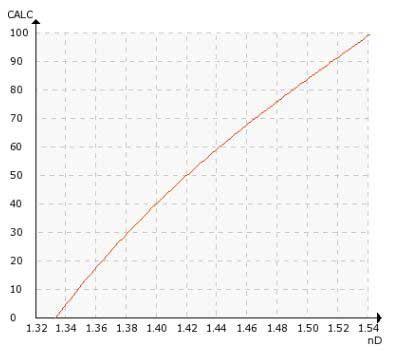

Chemical curve: R.I. per BRIX at Ref. Temp. of 20˚C

Application

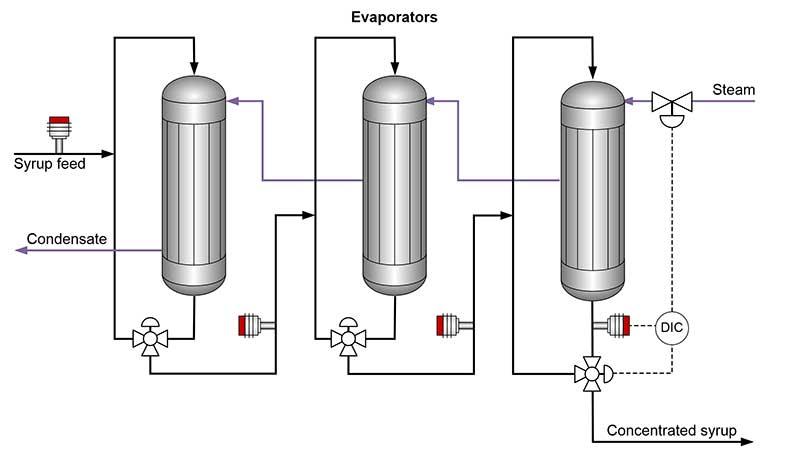

Falling film evaporators, with two or more effects, are frequently used by the liquid sweeteners industry. The evaporators with up to seven effects have been employed since the mid-seventies to offset rising energy costs. Evaporators are used to remove excess water from syrups and to raise the concentration to a predetermined level.

There are generally four variables involved in the equation used for evaporation control: inlet concentration, outlet concentration, steam flow and product flow. For the maximum efficiency and minimum steam consumption, all these variables must be coordinated.

Typical end products from sweeteners

(dextrose, fructose, glucose syrup, sorbitol):

- sweeteners for beverage

- beer brewing

- jams

- preserves

- sweets

- confectionery

- ice cream

- liqueurs

- pharmaceuticals, etc

Instrumentation and installation

Vaisala Polaris™ PR53 Process Refractometer suits perfectly for evaporator control. Usually, one refractometer is used to adjust the syrup feed (according to concentration) to the capacity of the evaporation plant (feed-forward control). Typical measurement range for the evaporator feed control is 0-35 %.

Another refractometer is used in the final effect outflow. It is typically installed in a control loop to keep the syrup concentration constant. This is done by adjusting the steam flow or the quantity of syrup returned to evaporation. Typical measurement range for the evaporator outlet control is 70-85%.

For optimized evaporator control, other refractometers can also be installed at the outflow for each single effect.

Precise concentration control at the evaporator outlet is very important for optimizing downstream processes, such as crystallization and adsorption separation.

Vaisala Polaris process refractometer

The Vaisala Polaris PR53AC Sanitary Compact Process Refractometer is for hygienic applications. Convenient installation directly to process lines with standard sanitary and Type N couplings, or with a sanitary flow cell. CIP and SIP cleaning.

Vaisala Polaris PR53AP Sanitary Probe Process Refractometer is for hygienic installations in large pipes, tanks, cookers, crystallizers and kettles. The long probe with common tank bottom flanges enables installation depths of up to 170 mm. The flush mount option allows installation in tanks with scrapers or mixers. CIP and SIP cleaning.

The Vaisala Polaris PR53GP Process Refractometer (pictured) is a heavy-duty instrument with nonweld body construction for diverse applications. The optional flange-mounted pipe flow cell installation accessory allows flange-mounted installation in a wide variety of pipe sizes.

User Interface

Vaisala Indigo520 transmitter integrates with Polaris PR53 process refractometers providing an expanded feature set, including a physical display for real-time measurement data and advanced diagnostics, more output options, data logging, and automated prism wash control. This combination enables efficient process monitoring and easy access to diagnostic information.

Measurement range

Refractive Index (nD) 1.3200 – 1.5300, corresponding to 0-100 Brix.