Lysine evaporation

Introduction

L-lysine is an amino acid essential for human and animal nutrition. It has a variety of industrial uses, including as a medicament, chemical agent, food material and feed additive.

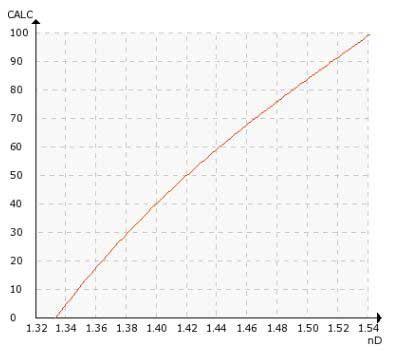

Chemical curve: R.I.per Brix at Ref. Temp. of 20˚C

Application

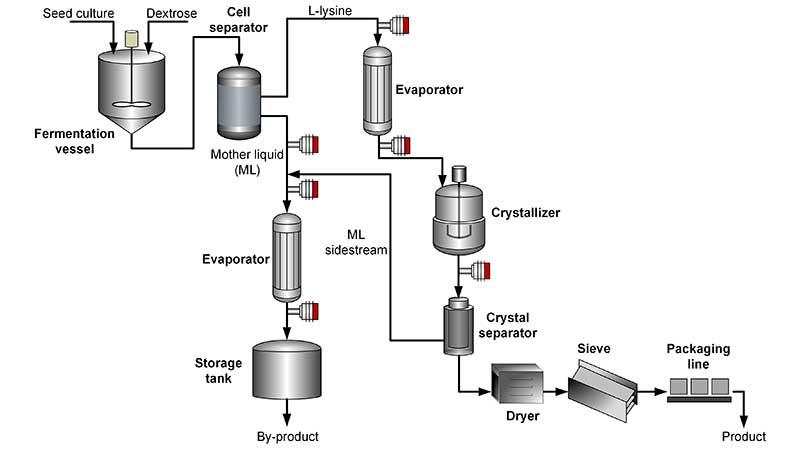

L-lysine is manufactured by microbial fermentation in bioreactors. The choice of raw materials for amino acid fermentation is geographically specific: sugar, molasses, dextrose/ glucose or starch as the carbohydrate source are added to the fermentation reactor along with seed culture as feed stock, for example, corn. Corn provides minerals and growth factors needed for lysine production. During fermentation period the temperature is about 30 to 35 °C (86 to 95 °F).

The lysine accumulates in the fermentation broth as an aqueous solution. After fermentation the lysine feed is separated into lysine broth and mother liquid by-product. The lysine feed is then concentrated by evaporation. The evaporation process is controlled using Vaisala Polaris™ PR53AC Sanitary Compact Process Refractometer to ensure a precise concentration level is reached.

The concentrated lysine material is then purified by crystallization to produce higher grades of lysine. The lysine content is typically above 60 % on dry matter. Control over the required grade of lysine after crystallization and before drying is performed with a Process Refractometer PR53GP. The product then goes through the sieve to packaging after which it is ready for shipment.

The by-product from lysine broth is concentrated and stored in tanks before shipment. The Process Refractometer PR53AC controls the mother liquid feed during the concentration, and Process Refractometer PR53GP is used to ensure the required concentration of the product before storage.

Typical end products of L-Lysine:

- feed additive

- food material

- health supplements.

Instrumentation and installation

In the L-lysine production process there are several points where Process Refractometer measurements are used for process control:

In L-lysine line:

- Monitoring of the fermentation reaction (see also application note Pharmaceutical Fermentation).

- Measurement of the concentration at the evaporation stage, range 0-100 Brix.

- Lysine crystallization (see also application note Pharmaceutical Crystallization), range 0-100 Brix.

In by-product line:

- Mother liquor feed concentration measurement before it is concentrated in the reactor.

- By-product concentration measurement after the mother liquor side stream has been added to the process before entering the reactor.

- Final by-product concentration measurement before storage.

The Sanitary Compact Refractometer PR53AC and Process Refractometer PR53GP are ideally suited for process control and monitoring in the L-lysine production process.

Due to its unique digital sensing technology, the refractometer is accurate and does not drift in the presence of bubbles or suspended particles. The refractometer is delivered factory calibrated and does not require re-calibration. Moreover, verification is easily performed using standard refractive index liquids.

Concentration monitoring with the refractometer ensures process efficiency, maximizes productivity and reduces operational costs.

Polaris refractometers

The Vaisala Polaris PR53AC Sanitary Compact Process Refractometer is for hygienic applications. Convenient installation directly to process lines with standard sanitary and Type N couplings, or with a sanitary flow cell. CIP and SIP cleaning.

The Vaisala Polaris PR53GP Process Refractometer (pictured) is a heavy-duty instrument with nonweld body construction for diverse applications. The optional flange-mounted pipe flow cell installation accessory allows flange-mounted installation in a wide variety of pipe sizes.

User Interface

Vaisala Indigo520 transmitter integrates with Polaris PR53 process refractometers providing an expanded feature set, including a physical display for real-time measurement data and advanced diagnostics, more output options, data logging, and automated prism wash control. This combination enables efficient process monitoring and easy access to diagnostic information.

Measurement range

Refractive Index (nD) 1.3200 – 1.5300, corresponding to 0-100 Brix.