Frequently asked questions

- What are the advantages of using a thin film polymer humidity sensor in a test chamber?

- How is humidity measured above the boiling point of water?

- How should the humidity sensor be installed inside the test chamber?

- Can different materials affect to the humidity sensors?

- How can sensor accuracy be maintained in test chambers?

- How to accurately measure in near condensing conditions?

- Product recommendations

1. What are the advantages of using a thin film polymer humidity sensor in a test chamber?

The biggest advantages of using capacitive polymer sensors (sometimes called electronic sensors) are a fast response time, low maintenance, and the ability of the sensor to operate over a wide temperature range.

Vaisala HUMICAP® polymer sensors can be used in test chambers over the range of -70 to +180 °C (-94 to 356 °F), as they are not limited by the freezing or boiling points of water.

The long term stability of Vaisala HUMICAP® sensors is excellent, usually requiring only an annual calibration. Expected sensor lifetime is 10 years or more, delivering a low total cost of ownership.

Unlike other technologies, the sensor does not need a wick, a water supply, a water tank, or associated service related to these components.

HUMICAP® sensors also respond faster and suffer less hysteresis, as they equilibrate with changing temperatures better than a water supply

2. How is humidity measured above the boiling point of water?

The Vaisala HUMICAP® thin film polymer sensor responds to water vapor, which is of course present at temperatures above and below the boiling point of water. However, there are physical limits to the maximum possible relative humidity value at any temperature above the boiling point. Here is the humidity theory that explains this:

The definition of relative humidity is: RH=Pw/Pws * 100%, where Pw is the water vapor pressure and Pws is the temperature dependent water vapor saturation pressure.

Pws is well known from the literature for temperatures up to the critical temperature of 373,98 °C/705,16 °F. The vapor pressure Pw is independent of temperature, and when Pw is known there is no problem in defining the Relative Humidity up to the critical temperature.

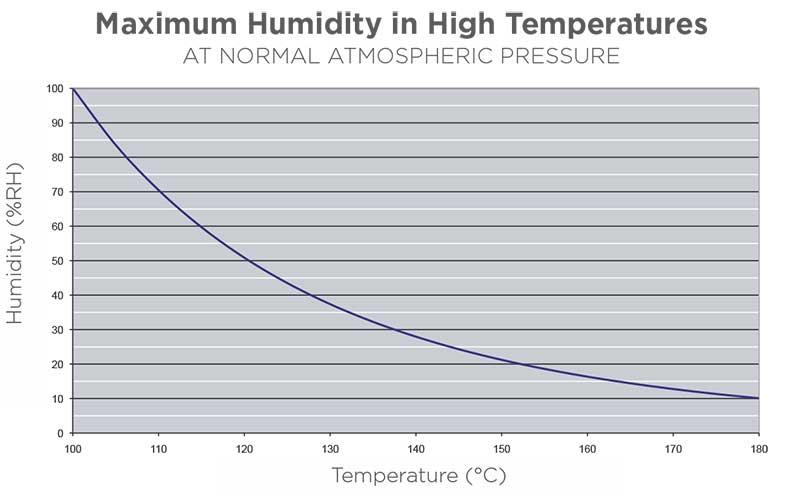

At temperatures above the boiling point there is a practical limit on the value of relative humidity (%RH) as the water vapor pressure cannot be higher than the total pressure. This means that the maximum relative humidity in unpressurized systems above the boiling point of water is always lower than 100%RH, as shown in the graph.

For instance, at the temperature of 120 °C (248 °F) the maximum relative humidity is 51% RH. This can be calculated knowing that saturation pressure Pws is approximately 1.987 bar (28,8 psia). In normal atmospheric pressure 1.01325 bar (14,696 psia) the highest possible Pw is also 1.01325 bar. This translates to 51%RH, which can be seen in Table 1.

Other humidity parameters, such as dew point temperature, also have a limit in unpressurized systems. For example, the maximum dew point is the same as the boiling point, typically 100 °C (212 °F).

The Vaisala HUMICAP® sensors have been verified for humidity measurement in both unpressurized and pressurized conditions in temperatures up to 180 °C (356 °F).

The Vaisala humidity calculator is an easy to use tool for calculation of all humidity parameters in different conditions.

3. How should the humidity sensor be installed inside the test chamber?

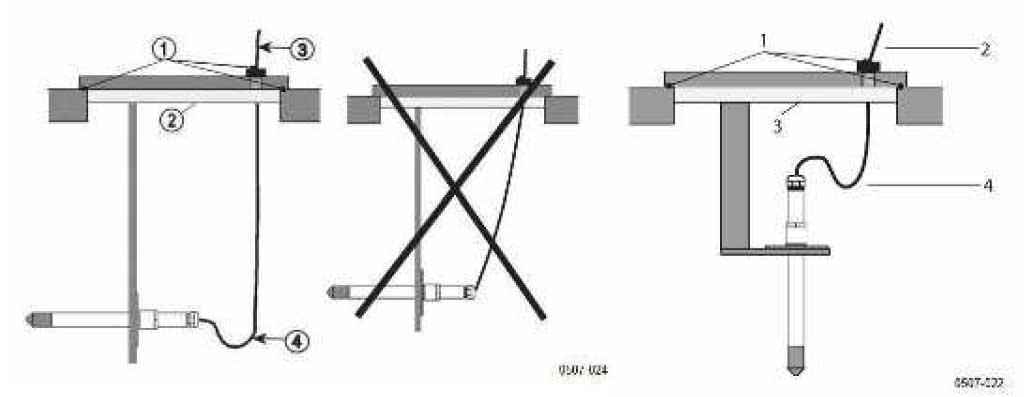

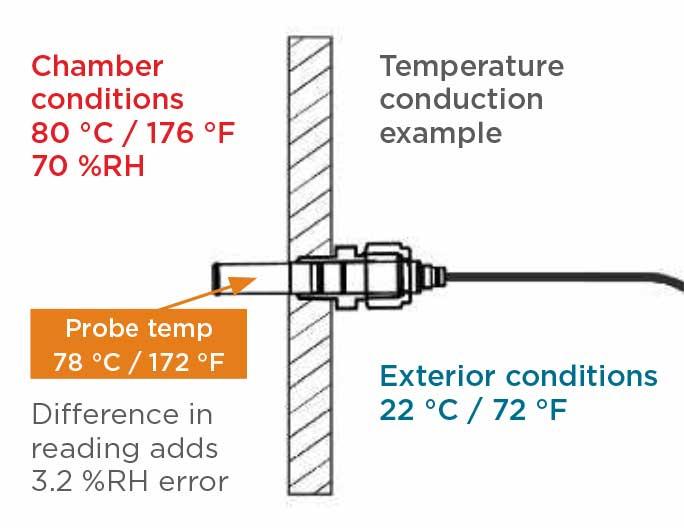

It is recommended that the humidity probe with a section of probe cable be mounted inside the chamber (see Figure 1) to make sure that whole probe is in temperature equilibrium with test chamber air. If the probe is installed through a chamber wall and there is a temperature difference between the tip and end of probe it can cause the sensor to be at a temperature different from the actual air. This would mean incorrect RH measurement, or even a condensation risk. For example in a chamber at 40 °C/95% RH there will be condensation on the probe if the probe temperature decreases by only 1 °C. Such a temperature effect could easily exist due to temperature conduction from the room outside of the chamber. See Figure 2.

- Horizontal mounting is preferred, this allows any water on the probe to flow off, instead of collecting on the sensor.

- Allow for a bend or slack in the cable

- Allow for temperature and pressure fittings

- Use insulation around probe installation area

- Ensure installation point is representative of airflow in the space

1 = To be sealed 2 = To be insulated 3 = Insulate the cable 4 = Let the cable hang loosely. This prevents condensed water running to the probe along the cable.

Vaisala humidity probes for measurement in test chambers are all fully leak tight. The seal around the probe cable feed through must also be leak tight. Vaisala offers different accessories for this purpose. The use of silicone material is one alternative, but this makes removal and reinstallation difficult and in some cases can cause measurement drift due to chemicals out gassing during material curing.

Figure2

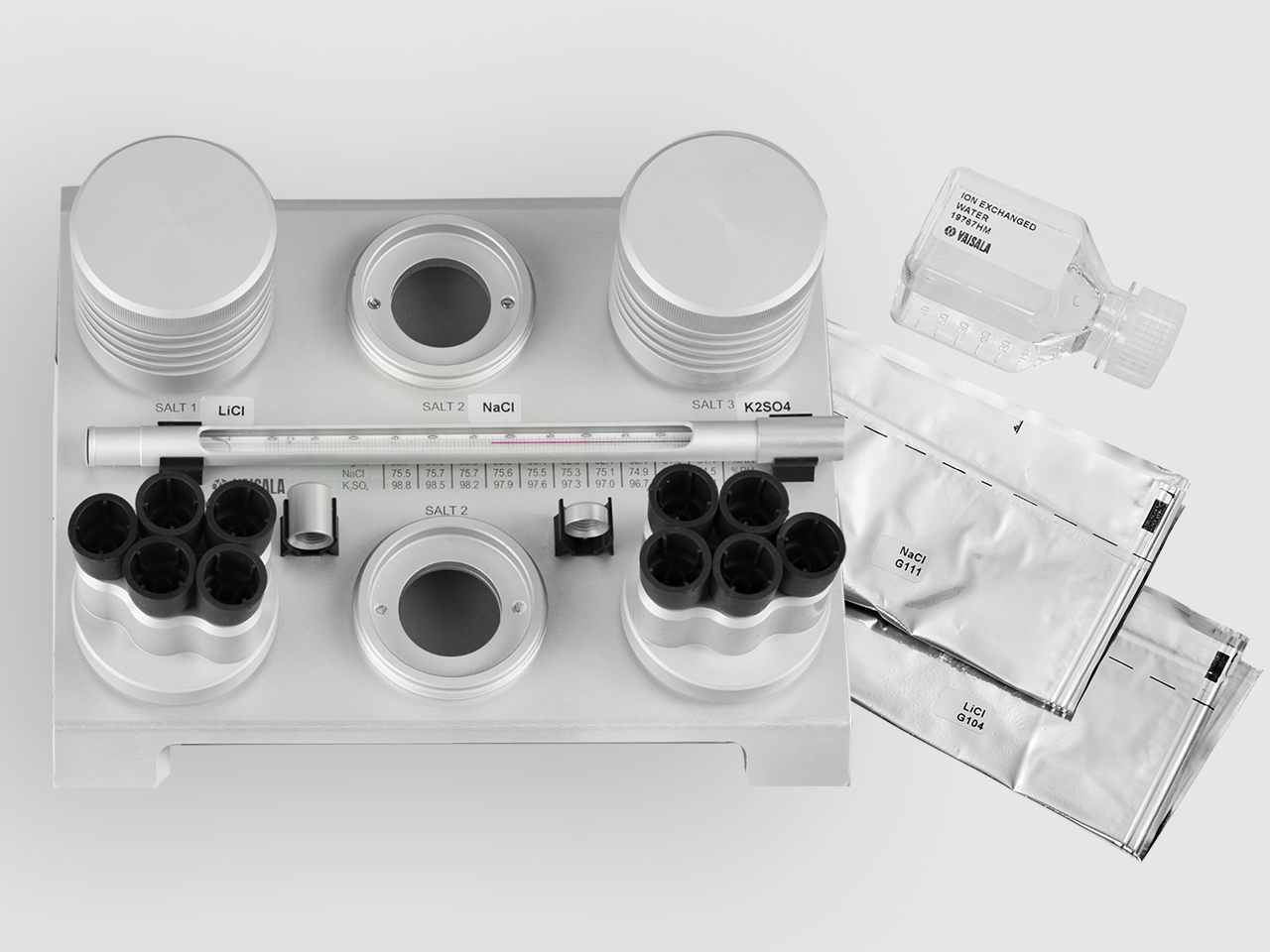

Consideration should also be given for humidity field calibrations when designing the probe installation. If a salt bath calibrator will be used, like Vaisala Humidity Calibrator HMK15, the probe should have a long enough piece of cable inside the chamber to allow for insertion of the probe into the calibrator.

4. Can different materials affect the humidity sensors?

Some sealing materials that are used for chamber wall or cable feed through sealing can cause humidity drift, increased response time, and hysteresis of the humidity instrument. This can happen when chemicals evaporate while the sealing material is curing. For example, normal household quality silicone sealants out-gas acetic acid or methanol during curing and should be avoided. Fortunately this effect is reversible and will fade away once the out gassing of these substances ends. The recovery to original sensor characteristics is faster at higher temperatures.

It is advisable to install the humidity instruments only after these materials are cured. If this is not practical, the yellow protective cap shipped with the Vaisala humidity probes may be used to protect the sensor while sealing materials are curing.

In chambers that are used for very dry conditions it is important to note that some sealing materials absorb humidity and will act as a moisture buffer. Even relatively small amount of these materials can delay drying of the chamber

Many different materials are tested and aged in test chambers. Some materials outgas chemicals that may affect humidity sensor accuracy. For conditions where normal HUMICAP® performance may be challenged,Vaisala can provide instruments with a sensor purge function that periodically heats the humidity sensor to remove any chemical contamination. Drift caused by improper sealing materials or other material out gassing is rarely a problem in sensor purge equipped devices.

For instruments not equipped with sensor purge, recovery can be made manually by heating up the chamber to 160 °C for one hour. This is usually enough to remove most typical contaminants from the sensor.

5. How can sensor accuracy be maintained in test chambers?

Long term measurement performance can be achieved through the selection of the right measurement technology, and the regular calibration of installed sensors.

To help with this, Vaisala offers multiple methods to calibrate and adjust your chamber instruments, from the HMK15 salt bath calibration kit, out Insight PC interface software, and our portable HM70 humidity and temperature meter.

The optimal solution for field calibration is to combine the HMK15 kit with the HM70 portable meter. The HM70 meter is the reference and provides a traceable calibration of the fixed instrument, while HMK15 kit allows you to calibrate at multiple relative humidity points. Factory calibration service options can help optimize measurement accuracy also.

6. How can I accurately measure in near condensing conditions?

The demand for testing in even higher humidity/higher temperature conditions has become more common. The standard testing conditions of 85% RH/85°C are now in many cases are being raised to 90%RH/90°C and even 95%RH/95°C. These conditions can be quite challenging for conventional humidity instruments, but can be accurately measured using the warmed probe technology featured in the Vaisala HMM170. Warming the probe body decreases the %RH seen by the sensor, avoiding condensation and allowing it to measure reliably in near 100% RH.

Product recommendations

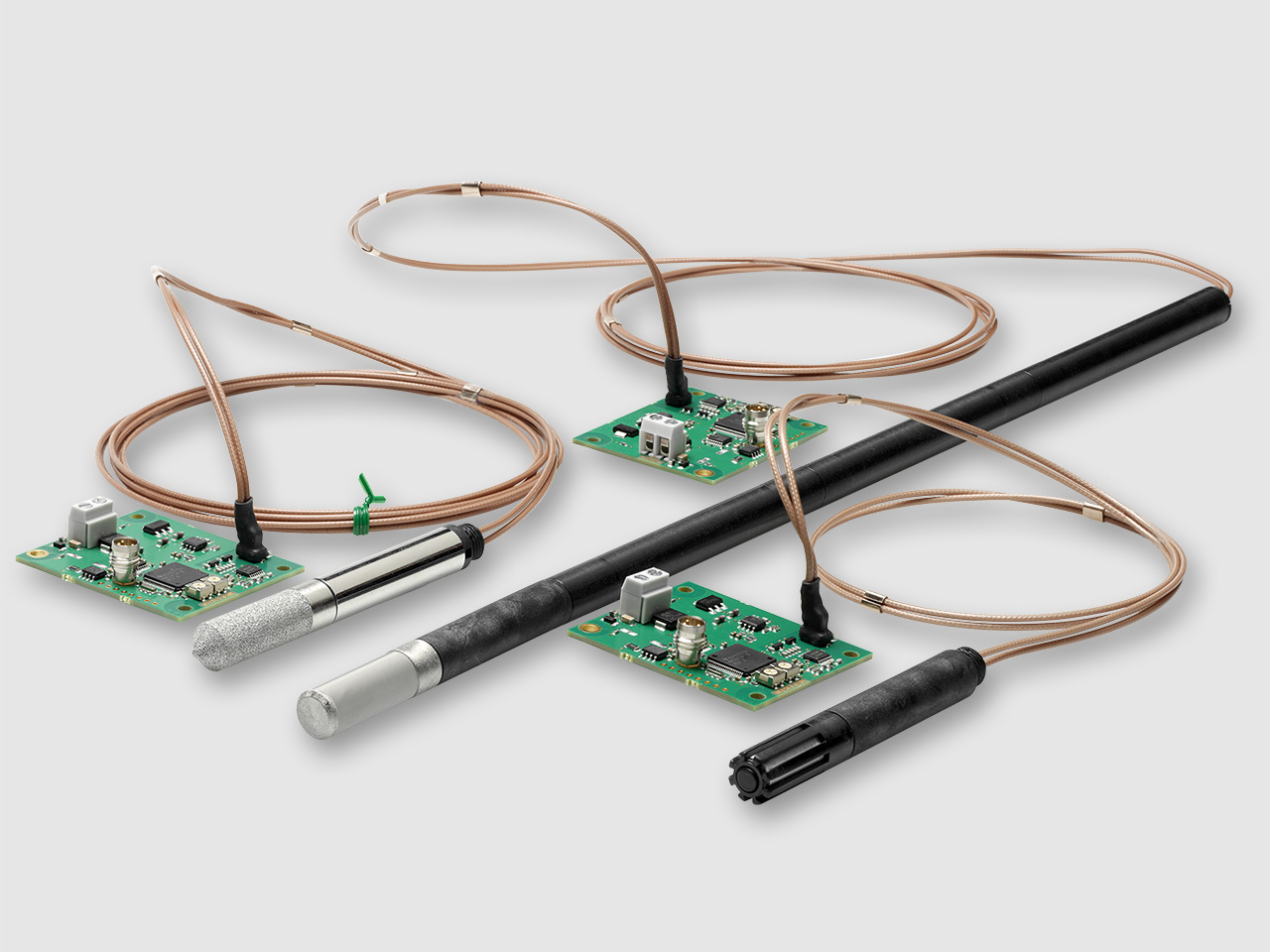

Humidity and Temperature Probe HMP110

Humidity Module HMM100

Humidity and Temperature Module HMM170