Cane sugar evaporation

Introduction

Evaporation is a crucial step in the sugar making process. The main purpose of the evaporation is to raise the sugar content in the juice to reach the saturated condition required for crystallization.

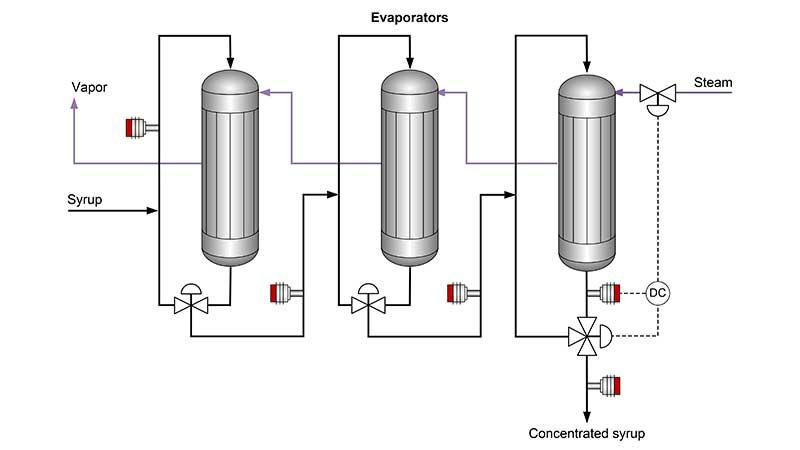

Evaporation usually takes place in a multiple effect evaporator heated with steam. Evaporators are the largest heat users and major contributors to losses in sugar cane factories. These factors make effective evaporator control crucial to overall factory efficiency.

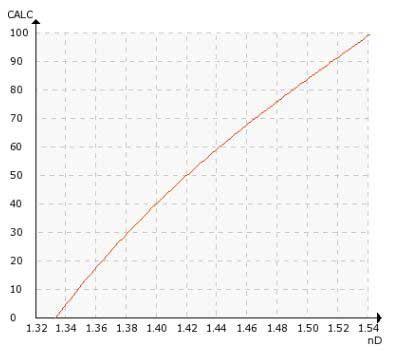

Chemical curve: R.I. per BRIX at Ref. Temp. of 20˚C

Application

The thin syrup (light-colored syrup) from the extraction plant is evaporated in multiple effect evaporators to concentrate it and to obtain the syrup which is fed to the pan station (crystallization). The dissolved solids concentration is raised from an initial concentration of 10-15 Brix to 50-75 Brix. The concentrated solution is known as heavy syrup.

Control of evaporation is crucial for the sugar factories. The main objectives for an evaporator control system are control of Brix and a smooth operation.

An optimally concentrated syrup improves the operation downstream and ensures a high product quality. If the syrup fed to the crystallizers exceed its limit, spontaneous nucleation can happen producing crystals out of specification which require reprocessing and increase the operating costs.

Good evaporation control also allows the evaporators to smooth out process fluctuations and to adjust automatically and immediately to the changes in the syrup flowrate.

Typical examples of cane sugar syrup's end products are:

- sugar and syrup for sweetening soft drinks

- beer brewing

- preserves

- beverage

- sweets

- liqueurs

- ethanol

Instrumentation and installation

Vaisala Polaris™ PR53 Process Refractometer is the ideal instrument for controlling sugar factory operations. The refractometer can be installed directly in the process line for continuous monitoring the Brix of the juice and syrup throughout the entire process. The Brix measurement by the refractometer is accurate and reliable and it is not affected by the presence of undissolved particles, crystals or bubbles.

The refractometer is installed in the inlet and outlet of evaporation as well as intermediate evaporation stages. The information given by the refractometer helps to optimize the process and ensure high-quality product for the downstream factory.

The PR53 refractometer provides a 4–20 mA output signal and supports Modbus RTU communication. When integrated with the Indigo520 transmitter, up to four 4-20mA outputs and Modbus TCP/IP connectivity are available for real-time process control. Sanitary models PR53AC and PR53AP are available with 3-A Sanitary and EHEDG certifications.

In the intermediate stages, the refractometer is used in a control loop that keeps the syrup concentration constant by regulating the steam flow, or by regulating the amount of syrup returned to the evaporator.

The refractometer also helps to maximize the storage capacity by maintaining automatically the concentrated syrup at a high-level of solids.

In some plants, the heavy syrup contains additives and supersaturated impurities (e.g. oxalic acid), which may crystallize on the prism. Therefore, an automatic steam wash is required. In some extreme cases, it is preferable to mount the refractometer in a narrow by-pass line downstream of a small cooling heatexchanger, where the impurities crystallize. Typical measurement range in this application is 50-80 Brix.

Vaisala Polaris PR53GP Process Refractometer

Description

The Vaisala Polaris PR53GP Process Refractometer is a heavy-duty instrument with nonweld body construction for diverse applications. The optional flange-mounted pipe flow cell installation accessory allows flange-mounted installation in a wide variety of pipe sizes.

User Interface

Vaisala Indigo520 transmitter integrates with Polaris PR53 process refractometers providing an expanded feature set, including a physical display for real-time measurement data and advanced diagnostics, more output options, data logging, and automated prism wash control. This combination enables efficient process monitoring and easy access to diagnostic information.

Prism wash systems

For applications with sticky process conditions the prism wash options are steam wash system, pressure wash system ja water wash system.

Measurement range

Refractive Index (nD) 1.3200 – 1.5300, corresponding to 0-100 Brix.