Beet sugar evaporation

Introduction

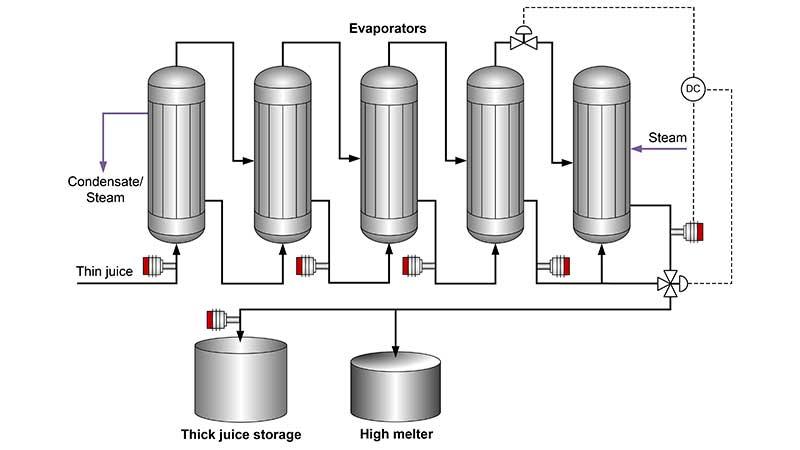

The evaporator station forms an important link between the juice production and crystallization steps of the sugar production plant. Usually, the evaporator station comprises 4 to 5 evaporator stages, of which the first ones consist of multiple evaporators. As the pressure in the evaporators is regulated, so that it decreases from stage to stage, the juice passes sequentially through all the stages.

Once the required concentration is reached, the thick juice is discharged from the last stage of the evaporator station.

A general requirement is that the concentration of thick juice in the evaporator outlet should be as high as possible, reaching 68-75 % dry substances in modern factories. It is then possible to apply crystallization technologies, which ensure a high sugar quality and facilitate low energy consumption.

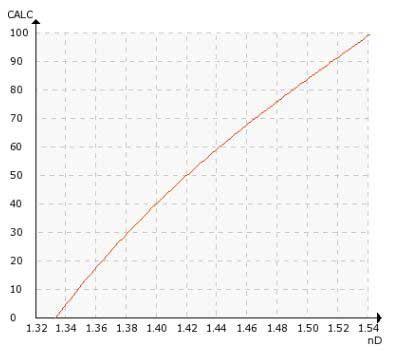

Chemical curve: R.I. per BRIX at Ref. Temp. of 20˚C

Application

Evaporator Plant Feed

Appropriate feed concentration control for an evaporation plant is essential for optimal results. Normally Vaisala Polaris™ Process Refractometer signal is used to adapt the feed of the thin juice to the capacity of the evaporation plant (using feedforward control).

The refractometer signal can also be used for keeping the feed concentration to the evaporation plant constant by the controlled addition of thick juice to the incoming thin juice. This measurement is made after mixing to maintain precise control of the mix.

Evaporator Plant Outlet and Intermediate Effects Control

Evaporation in the multiple-effect evaporation plant is more cost effective than in the crystallizer, which economically justifies an evaporation control system. The Process Refractometer is not only used after the final evaporation stage, but also after the intermediate stages.

The refractometer is also used in a control loop, which keeps the thick juice concentration constant by regulating the steam flow or the quantity of the thick juice recirculated to the evaporators. As a result, the specific energy consumption can be minimized.

Thick Juice to Storage Tank

In this application, the process refractometer helps to maximize the storage capacity by keeping the thick juice at as high a concentration level as possible.

Typical examples of beet sugar juice's end products are:

- sugar for sweetening soft drinks

- beer brewing

- pastries

- preserves

- sausages

- beverages

- sweets

- confectionery

- ice-cream

- liqueurs

- pharmaceuticals

Instrumentation and installation

Vaisala Polaris PR53GP Process Refractometer is an ideal instrument for measuring Brix in the demanding beet sugar evaporation process. The refractometer is installed via a flange or a clamp connection.

Lime residuals and other additives may coat the prism and an automatic steam wash is recommended in thin juice applications with typical range of 0-25 Brix.

In some plants, the thick juice also contains supersaturated impurities (e.g. oxalic acid), which may crystallize on the prism. Therefore, an automatic prism wash with hot high-pressure water may be necessary. In extreme cases, the refractometer can be installed in a narrower by-pass line flowing from a cooling heat exchanger, where the impurities crystallize.

Because of its digital sensing technology, the refractometer can measure dissolved sugar uninfluenced by the presence of undissolved particles and crystals.

Vaisala Polaris PR53GP Process Refractometer

Description

The Vaisala Polaris PR53GP Process Refractometer is a heavy-duty instrument with nonweld body construction for diverse applications. The optional flange-mounted pipe flow cell installation accessory allows flange-mounted installation in a wide variety of pipe sizes.

User Interface

Vaisala Indigo520 transmitter integrates with Polaris PR53 process refractometers providing an expanded feature set, including a physical display for real-time measurement data and advanced diagnostics, more output options, data logging, and automated prism wash control. This combination enables efficient process monitoring and easy access to diagnostic information.

Prism wash systems

For applications with sticky process conditions the prism wash options are steam wash system, pressure wash system ja water wash system.

Measurement range

Refractive Index (nD) 1.3200 – 1.5300, corresponding to 0-100 Brix.