Exceeding the high-precision demands of integrated circuit manufacturing: the role of Vaisala’s instruments in cleanrooms

The client: China Electronics System Engineering CEFOC and semiconductor manufacturer Beijing Memory Technologies, Inc. (BJMT)

The challenge: create a cleanroom environment with a monitoring system capable of monitoring really tight temperature and relative humidity tolerances

The solution: Vaisala HMT370EX, Vaisala HMT120 and Vaisala HMT330. All perfect for the challenging process conditions delivering superior measurements

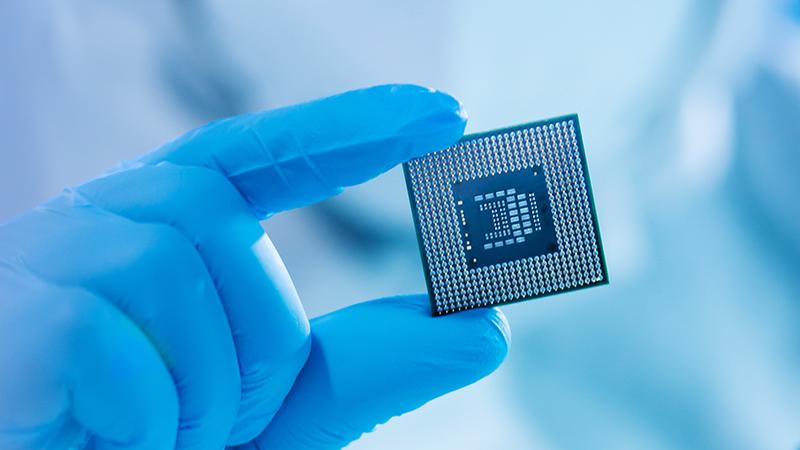

In the global consumer goods market, the demand for integrated circuits (ICs) continues to surge. Growing markets for products like alternative fuel vehicles, intelligent driving systems, intelligent terminals, and 5G mean that this demand is unlikely to slow any time soon.

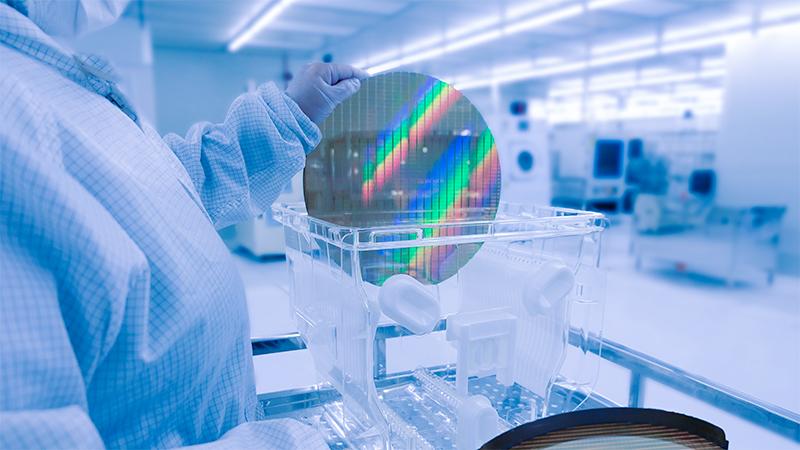

As a high-precision industry, IC manufacturing has extremely strict requirements regarding its entire production process and environment, and perhaps this is most important when it comes to the need for properly constructed IC cleanrooms. In IC factories, operators must wear tightly sealed protective clothing and shoe covers, and then pass through several separate isolated gates before entering the cleanroom. Additionally, the environment within IC cleanrooms must be carefully monitored and controlled with regard to such factors as temperature and humidity.

Higher cleanroom standards require more accurate monitoring

China Electronics System Engineering (CEFOC) was one of the earliest companies in China to specialize in the installation of electrical and mechanical cleanroom equipment. They provide comprehensive "turnkey" engineering services covering design, procurement, project management, construction, and facility management, plus the manufacture of products related to cleanroom processes, for IC manufacturing enterprises.

In 2021, semi-conductor manufacturer Beijing Memory Technologies, Inc. (BJMT) needed new IC cleanrooms, and they had specific requirements regarding high precision and high stability environmental monitoring. Working closely together on this project, CEFOC and Vaisala successfully installed the Vaisala HMT330 industrial temperature and humidity transmitter, the Vaisala intrinsically safe temperature and humidity transmitter HMT370EX, and Vaisala temperature and humidity transmitter HMT120 series products to the cleanroom of the new BJMT cleanrooms. Since installation, BJMT reports that all these Vaisala instruments and transmitters have run stably and measured accurately.

The Vaisala HMT330 delivers accurate measurements in harsh environments and under demanding requirements, and can also be customized for different application environments to meet diverse customer needs.

Vaisala’s measurement accuracy delivers superior performance

Producing the new, smaller 28nm chips requires a cleanroom environment with a temperature measurement accuracy of maximum ±0.3°C and a relative humidity measurement accuracy of maximum ±3%. If the temperature and humidity parameters are exceeded, IC product yield, performance, and reliability will be significantly impacted. Zhang Qi, the Marketing Management Center general manager with CEFOC, comments, "The measurement accuracy of Vaisala products not only fully meets cleanroom design standards, but also significantly narrow the range of standard errors. It is reduced to one-third of the benchmark error, i.e., humidity ±1% and temperature ±0.1°C, which guarantees the reliable operation of the cleanroom.” Zhang Qi adds, "For the overall accuracy and stability of the project, Vaisala's measuring instruments became the ideal choice for this project.”

Zhang Qi continues, "As early as 2020, during the bidding phase of the BJMT cleanroom project, we knew that Vaisala's products could fully meet the customer's demanding requirements for temperature and humidity measurement. For this reason, our bid included Vaisala’s measuring instruments, and since this time our cooperation with Vaisala has continued to deepen. The measurement accuracy of Vaisala products not only fully meets cleanroom design standards but also significantly narrows the range of standard errors, reducing it to one-third of the benchmark error, i.e., humidity ±1% and temperature ±0.1°C. This guarantees the reliable operation of the cleanroom, making Vaisala's measuring instruments the ideal choice for this project.”

The Vaisala HMT370EX will not cause accidents or equipment damage even in the event of misuse or malfunction. The product has obtained a number of intrinsic safety certificates to date. In addition to measuring relative humidity and temperature, HMT370EX also supports the output of other humidity parameters such as dew point temperature, wet bulb temperature, absolute humidity, mixing ratio, water concentration, water mass fraction, water vapor pressure, and enthalpy.

Timely delivery is just as important as increased precision

For high-precision construction projects like this one, timeliness can be just as important as the precision of the technology being installed. There is often a tight delivery schedule for products and materials needed for a project, and the absence of a key material will directly affect the entire schedule.

The global COVID-19 pandemic added uncertainty to the availability of products, making timely delivery even more critical. The project cycle for BJMT was very tight, and high-quality measurement products were crucial for completing the project on schedule. Despite product supply shortages, Vaisala and its dealers guaranteed the products required for the project even before the formal purchase contract was signed. Vaisala ensured the full coordination of internal and external resources to deliver the key products on the agreed timetable.

In summary, by meeting the demanding requirements of high-precision IC manufacturing, Vaisala's products not only fully meet cleanroom design standards but also significantly narrow the range of standard errors, reducing it to one-third of the benchmark error. As a result, Vaisala's measuring instruments became the ideal choice for BJMT's cleanroom project, and the rapid response – even from an ocean away and with widespread sourcing bottlenecks to contend with – ensured timely delivery.

As Zhang Qi puts it, “Vaisala also won the favor and trust of CEFOC with its stable and reliable product performance, excellent products, and rapidly responding service. We are confident that Vaisala will engage in even deeper strategic cooperation with CEFOC in the near future, helping both parties' brands build an even stronger presence in construction and application scenarios for more precision products.”

The Vaisala HMT120 being installed in the facility, with a screen protection sticker still on. The HMT120 is a temperature and humidity transmitter built for cleanrooms and similar environments, with intelligent measuring probes that can be replaced in the field so as to trace the measurements easily.