Permanent lidar for wind farm operations

WindCube®: the smart alternative to permanent met masts

As wind energy projects grow in scale and complexity, accurate, reliable wind data has never been more critical. Traditionally, permanent meteorological (met) masts have been the industry standard for wind measurement. Today, however, remote sensing technology offers a smarter, more flexible alternative to replace or complement met masts in wind farm operations.

WindCube systems function as virtual met masts, delivering high-quality wind data while significantly reducing cost, risk, and operational complexity.

A virtual met mast for modern wind farms

WindCube integrates seamlessly with existing wind farm infrastructure, supplying real-time data to SCADA and farm performance monitoring systems via MODBUS TCP communication. Recognized by most ISOs (International Organization for Standardization) for wind farm data collection requirements, WindCube delivers continuous, high-accuracy data, reducing wind resource uncertainty.

By delivering reliable and continuous measurements, WindCube helps reduce wind resource uncertainty and supports better operational decision-making throughout the life of the project.

Whether used as a replacement for a met mast or as a complementary solution, WindCube offers a future-ready approach to wind measurement.

Met masts vs. WindCube: ownership cost

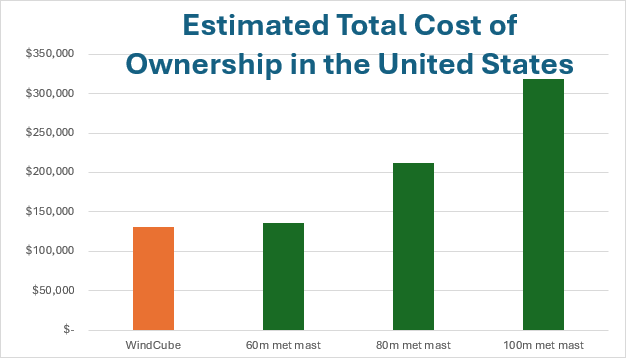

From a total cost of ownership perspective, WindCube presents clear advantages over traditional met masts. Unlike met masts, which often involve unpredictable maintenance and repair expenses, WindCube ownership costs are highly predictable. With the option to extend the warranty, operators can lock in stable costs over the system’s lifetime, minimizing financial surprises.

Because WindCube is a ground-based sensor, it requires no special safety procedures or permitting. This contrasts sharply with met masts, which involve climbing, working at height, and extensive safety and regulatory requirements. WindCube maintenance can be handled in-house, supported by free online Level 1 training that further reduces operating expenses.

Technology trends also matter. As WindCube technology continues to evolve, costs tend to decrease over time. Met masts, by contrast, rely heavily on raw materials such as steel, whose rising prices can drive long-term cost increases.

Installation timelines further highlight the difference. WindCube units can be deployed quickly after a typical four-week lead time, while met mast installations often require lengthy planning, permitting, and construction schedules.

Total (ten-year) cost of ownership comparison between WindCube and various meteorological masts. Met masts’ costs are estimated and averaged based on inquiries with installers and developers. All costs include maintenance and warranty extensions.

Key advantages of WindCube over met masts

WindCube systems deliver measurable benefits across safety, performance, and operational efficiency. By eliminating the need for tall structures, they significantly reduce health and safety risks associated with installation and maintenance. Their ability to measure wind across the entire turbine sweep provides more representative data for turbine performance analysis and long-term asset optimization.

With no permitting requirements, minimal site disruption, and self-sufficient maintenance supported by free training, WindCube lowers operational complexity while improving data quality. The continuous dataset it provides can also support future repowering assessments, making it a valuable long-term asset for wind farm owners and operators.

A smarter way forward

In an industry where precision, safety, and cost control are paramount, WindCube stands out as a modern alternative to permanent met masts. By combining accurate wind measurement, reduced operational risk, predictable costs, and fast deployment, WindCube enables wind farm operators to make better decisions—today and well into the future.

How can I learn more?

Visit us at: Wind Energy

Additional questions? Contact us