Cutting waste and emissions in oil and gas industry with real-time monitoring – The Vaisala Polaris PR53GPEX Process Refractometer is the best choice for the industry

Summary

Sustainability: Vaisala Polaris process refractometers support sustainability in the oil and gas industry by enabling real-time, calibration- and maintenance-free concentration measurements that optimize resource use and reduce emissions.

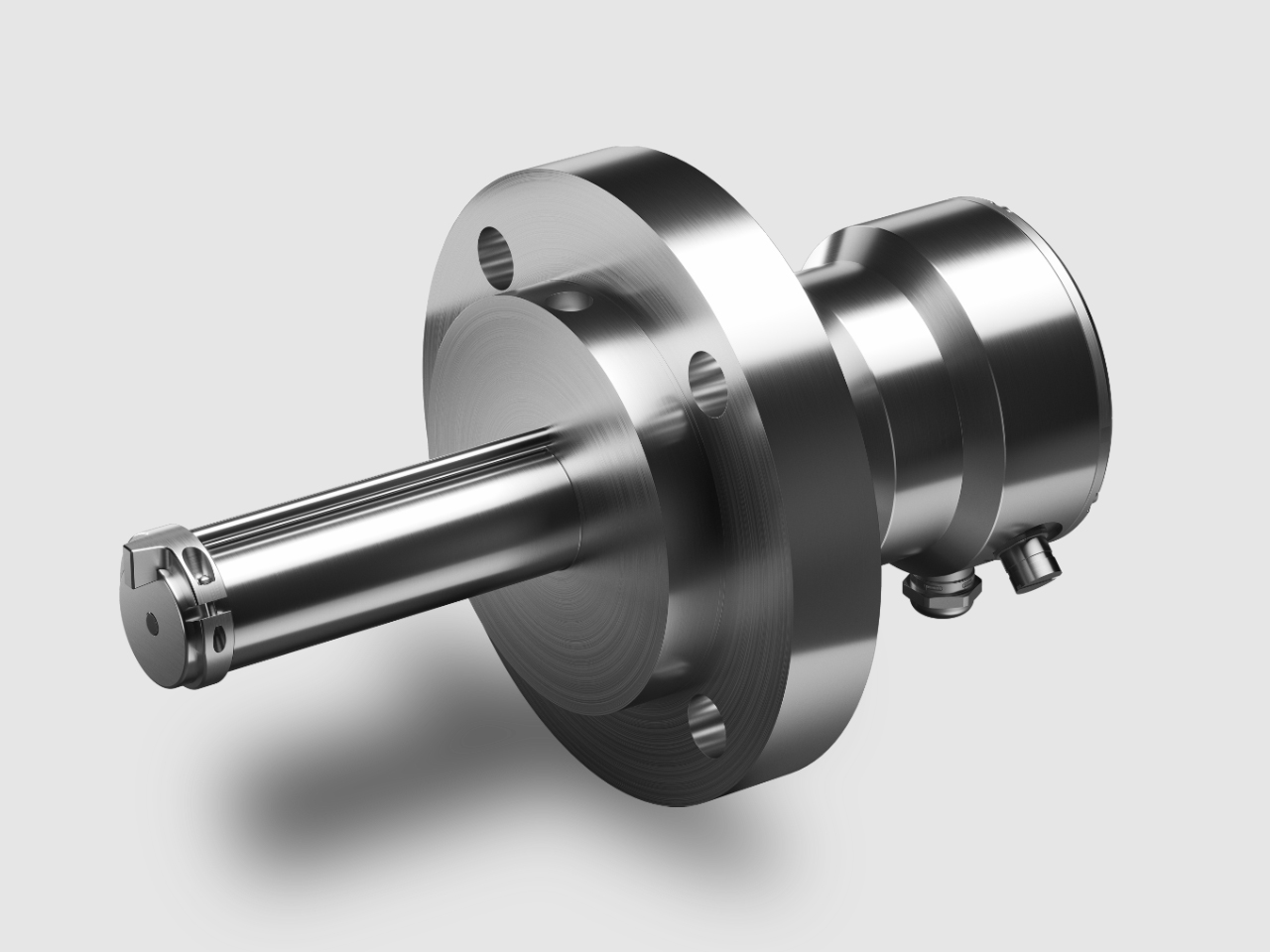

Harsh conditions: The Vaisala Polaris PR53GPEX model, with Hastelloy-C wetted parts and Ex-certification, is built for demanding refinery environments, eliminating the need for extra certifications and reducing downtime.

Efficiency and cost savings: By improving process control in applications, such as alkylation and carbon capture, Vaisala process refractometers help lower chemical usage, cut operational costs, and reduce environmental impact.

As the world is transitioning to greener energy sources, reducing emissions and environmental impact of the oil and gas industry is more important than ever. For this reason, the continued sustainability efforts in oil and gas are critical – here the Vaisala process refractometers make a difference.

Calibration and maintenance-free measurement

Vaisala PR53 Process Refractometers enable measurement of liquid concentration through the refractive index of a liquid. Refractive index is measured through detection of the angle of the reflected light at the boundary of the measurement window and process liquid, read more about the measurement of refractive index here: Refractive index, technology

Vaisala’s inline process refractometers are designed for continuous, real-time monitoring. Process refractometers are often used in industrial applications where precise control over liquid concentration is necessary, including the oil and gas industry.

The Vaisala PR53GPEX Process Refractometer is available with an option designed especially for refinery usage, the RP. With appropriate wetted part material choice of Alloy C276, often known as Hastelloy-C, and enhanced monoblock-construction, it is designed for harsh environments like nitric and caustic acid. With the combination of being Ex-certified to Zone 2 or 0 depending on selected option and the seamless weld-free wetted parts, the product is convenient for the user as additional certificates or tests often related with welds or hazardous areas are not necessary. The constructional choices and the inherent robustness of the technology provide drift- and maintenance free normal operation. In large-scale installations with thousands of sensors, this translates to significant time and cost savings.

Helping to make oil and gas processes more sustainable

Using a Vaisala process refractometer in the oil and gas industry improves process efficiency and reduces waste. Since process refractometers measure the concentration of liquids in real time, operators can monitor and adjust processes more precisely. In oil refining and petrochemical production, accurate concentration data can optimize the use of raw materials, reduce energy consumption, and minimize the need for chemical additives.

For example, in the alkylation process where alkylate for increasing the octane of gasoline is produced, sulfuric acid concentration can be accurately measured and optimized – potentially saving tens of tons of acid at a plant. This reduces costs while minimizing the environmental impact of the process and converts waste streams to valuable product.

A PR53GP process refractometer can also help enable carbon capture and storage by optimizing amine concentration in scrubbing units. This allows efficient CO2 removal, reducing amine costs and environmental footprint.

By making processes more efficient, the Vaisala PR53GPEX process refractometer helps oil and gas companies save money, reduce their environmental impact, and conserve resources.

How can we help your oil and gas process? Contact us to discuss more

Add new comment