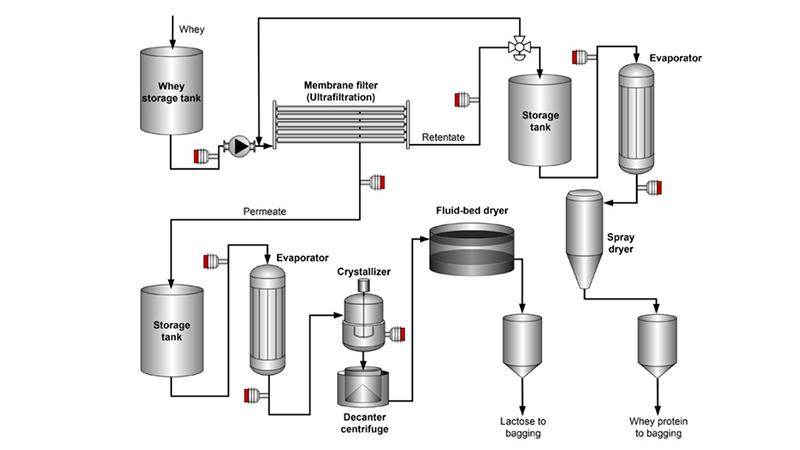

Whey separation process

Introduction

Whey is a liquid residue of cheese and casein production, which contains a large amount of food protein. Whey comprises 80-90 % of the total volume of milk entering the process. It also contains about 50 % of the nutrients of the milk: protein, lactose, vitamins and minerals. Whey Protein Concentrate (WPC) is processed by ultrafiltration (UF). Reverse osmosis (RO) or diafiltration are also used. UF is the most widely used process of membrane filtration (fractionation) in the dairy industry. The process works on the principle that a membrane restricts the passage of particles over a certain size. For example, in UF large particles like fats and proteins are retained (retentate), while small particles, like salts and sugars, pass through the membrane (permeate).

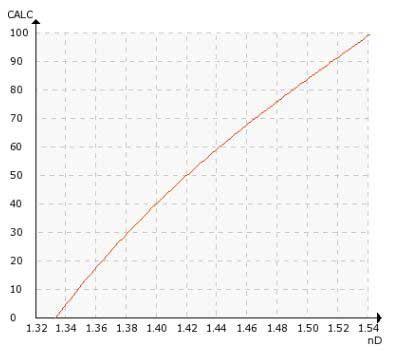

Chemical curve: R.I. per BRIX at Ref. Temp. of 20˚C

Application

Whey is processed as soon as it is collected to reduce bacterial activity. The process starts with the separation of fines and fat, followed by Ultrafiltration (UF). In UF, the whey is passed through a membrane filter to separate the whey protein as a retentate and lactose as the permeate. After separation both products are concentrated by evaporation. For a powdered product, the whey protein is fed to a spray dryer. The lactose is crystallized and separated from the mother liquor by centrifugation and dried in a fluid bed dryer. The final powdered products are then bagged.

Whey Protein Concentrate (WPC) is a powder, which contains 35-85 % protein in dry matter. To obtain more than 80 % protein concentration, it is necessary to diafilter, add water to the UF feed to wash out low molecular components, to remove more lactose and to raise the protein concentration in relation to total dry matter.

Lactose is the main constituent of whey and there are two basic methods of lactose recovery. The crystallization of untreated but concentrated whey, and the crystallization of whey, from which the protein has been removed by UF. After UF, the whey is first concentrated to 60-62 % dry matter by evaporation, and then it is transferred to crystallization tanks, where seed crystals are added to it. After crystallization, the crystals are separated by centrifuges and dried into powder in fluid bed driers. Before packing the lactose is also ground and sifted.

Typical end products from whey protein and lactose:

- whey protein concentrate (WPC)

- whey powder

- lactose

- casein.

Instrumentation and installation

In both, the whey and lactose processing applications, Vaisala Polaris™ PR53AC Process Refractometer is used to control the correct feed product concentration for the following process step. Typically, the refractometer is installed on a pipe bend. It is angle mounted on the outer radius of the pipe bend directly or by using a flow cell. This way the best flow conditions and self-cleaning effect can be achieved.

The refractometer helps to control and adjust concentration levels after the ultrafiltration, and at the evaporator inlet. The concentration measurement from the evaporator outlet helps to optimize energy consumption. It also ensures the correct feed product concentration to the spray dryer or crystallizer.The refractometer is installed directly in the crystallizer to monitor the supersaturation of the lactose solution, and to determine the exact seeding point.

If an instrument is used in the RO process, it has to be mounted outside the loop, due to the high process pressure of about 40 bar. Typically, prism wash is not required for any of these applications, since the plants are CIP cleaned every 10-20 hours. Typical process temperature for whey application is 10-70 ºC (50-158 ºF) and the measurements vary between 0 and 85 Brix.

The high accuracy control achieved with our precise in-line concentration measurement helps to improve the quality of the final product and to reduce operating costs. Additionally, the refractometer has a built-in web server that can be accessed via Ethernet, which significantly improves its ease-of-use. Obtaining realtime measurement data displays and diagnostics, altering instrument configuration settings or updating program versions can all be done remotely from the control room.

Vaisala Polaris PR53AC Sanitary Compact Process Refractometer

Description

The Vaisala Polaris PR53AC Sanitary Compact Process Refractometer is for hygienic applications. Convenient installation directly to process lines with standard sanitary and Type N couplings, or with a sanitary flow cell. CIP and SIP cleaning.

User Interface

Vaisala Indigo520 transmitter integrates with Polaris PR53 process refractometers providing an expanded feature set, including a physical display for real-time measurement data and advanced diagnostics, more output options, data logging, and automated prism wash control. This combination enables efficient process monitoring and easy access to diagnostic information.

Measurement range

Refractive Index (nD) 1.3200 – 1.5300, corresponding to 0-100 Brix.