Tomato paste evaporation

Introduction

It is vital that the tomato concentrate processing line operates constantly at a full capacity. It is not possible to work at reduced capacity, intermittently or every other day. Every time the tomato processing line is shut down, all the machinery must be cleaned. This involves several working hours, the consumption of a great amount of water and wastage of the product contained in the evaporator.

Furthermore, fresh and ripe tomatoes cannot be held in storage for processing at ambient temperatures over 30 °C (86 °F) for more than 24-48 hours. This will result in an inferior, low quality final product with a low Brix level.

The entire production cycle is carried out according to extremely stringent sanitary and hygiene standards.

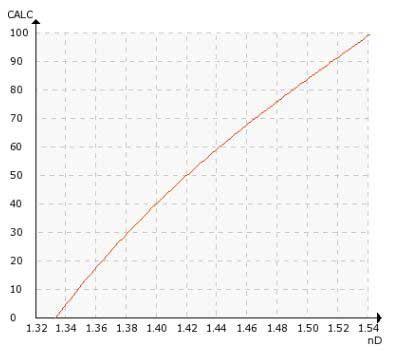

Chemical curve: R.I. per BRIX at Ref. Temp. of 20˚C

Application

Tomato juice concentration involves the reduction of the water content, leaving all the original solids as a concentrated solution.

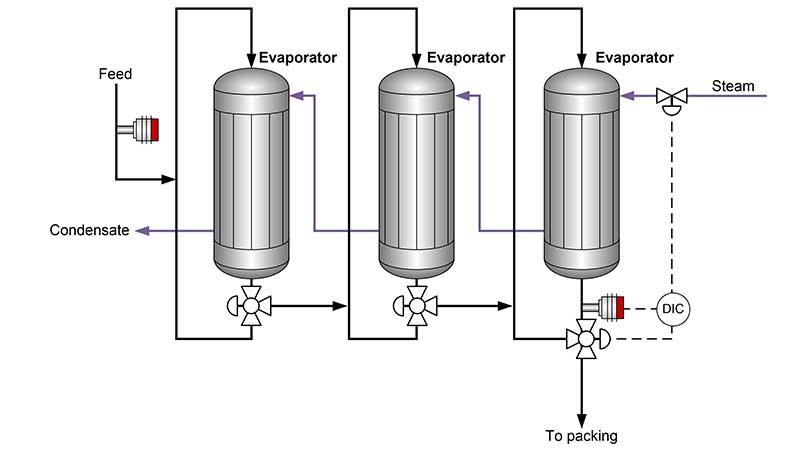

Typically, single or multiple-stage (also called effect) evaporation plants are used for the tomato concentrate production. The juice inside the evaporator flows through different stages, where its concentration level will gradually increase until the required density is obtained at the final stage. Here, the tomato paste is automatically extracted via a pump controlled by the Process Refractometer.

Typical end products from tomato concentrate:

- tomato concentrate

- tomato paste

- tomato puree

Instrumentation and installation

Vaisala Polaris™ PR53AC Process Refractometer provides continuous concentration information to optimize the evaporators performance while reducing energy consumption.

The refractometer is installed on the evaporator outlet. The signal from the refractometer adjusts the evaporator inlet flow or the steam flow to regulate the final Brix value. Typical measurement range is 5-35 Brix and typical process temperature about 95 ºC (203 ºF).

The refractometer is also used for tomato pulp standardization control. Typical measurement range is 4-7 Brix and typical process temperature about 20 ºC (68 ºF).

Vaisala Polaris PR53AC Sanitary Compact Process Refractometer

Description

The Vaisala Polaris PR53AC Sanitary Compact Process Refractometer is for hygienic applications. Convenient installation directly to process lines with standard sanitary and Type N couplings, or with a sanitary flow cell. CIP and SIP cleaning.

User Interface

Vaisala Indigo520 transmitter integrates with Polaris PR53 process refractometers providing an expanded feature set, including a physical display for real-time measurement data and advanced diagnostics, more output options, data logging, and automated prism wash control. This combination enables efficient process monitoring and easy access to diagnostic information.

Measurement range

Refractive Index (nD) 1.3200 – 1.5300, corresponding to 0-100 Brix.