Pectin extraction and evaporation

Introduction

Pectin is an acidic polysaccharide that occurs in the cell walls of a fruit. Pectin has excellent water binding and gel forming properties even at low concentrations. For this reason, the main use for pectin is as a food additive for gelling, thickening and stabilizing in the food industry. Pectin is also used in the cosmetics industry in the manufacture of oils and creams, paints, toothpaste and shampoos, and in the manufacture of wound healing preparations and gel caps for the pharmaceutical industry.

The major sources of pectin are citrus peels, the waste from extraction of lemon and orange juices, and apple pomace, the dry residue from the extraction of apple juice. Therefore, pectin is a by-product of either cider or juice production.

The largest pectin plants today are in Europe and Latin America.

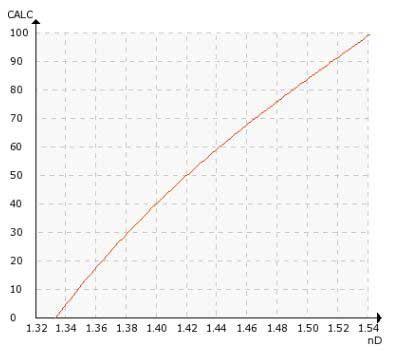

Chemical curve: R.I. per BRIX at Ref. Temp. of 20˚C

Application

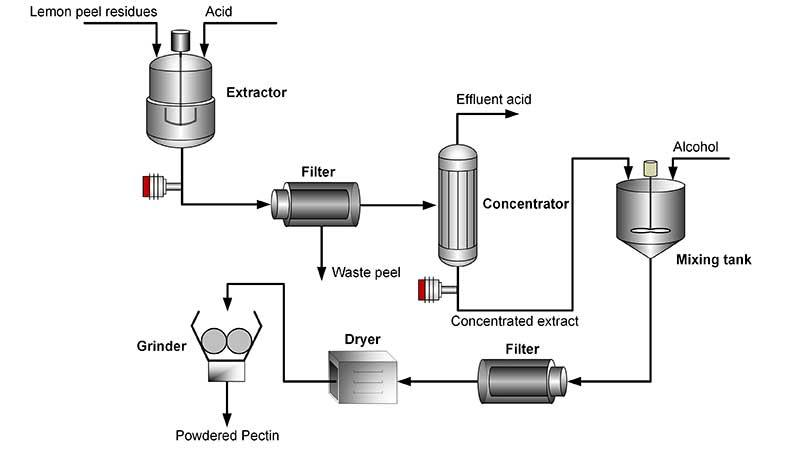

Although there are various alternative processes, most pectin is produced by the extraction from the raw material with hot aqueous mineral acid. The process is known as acid hydrolysis and the most commonly used acid is hydrochloric acid (HCl).

The process conditions are developed by the manufacturer to suit the major type of raw material processed in the plant, and to promote the production of the desired pectin type. The acid hydrolysis results in a slurry containing a solid residue which is easily separated by filtration or centrifugation.

After a concentrating step, the concentrated extract is treated to isolate the pectin. The most commonly used method is to mix the extract with an organic solvent in which pectin is insoluble, but which will allow many of the impurities to remain in the solution. International food standards permit the use of only methanol, ethanol or isopropanol as the organic solvent. At this stage, the pectin is a firm precipitate that can be easily separated by a physical separation technology.

The isolated pectin precipitate may be washed successively with alcohol of increasing strength, finishing with pure alcohol. This results in a fibrous pectin that is dried and ground to a fine powder product.

Typical end products from pectin slurry, pectin extract:

- powdered pectin

Instrumentation and installation

Vaisala Polaris™ PR53A Process Refractometer measures continuously the concentration of the liquid pectin extract to ensure optimum control and the highest product quality.

The refractometer can be installed directly in the reaction vessel or at the outlet pipe to provide real-time information on the amount of extracted pectin, thus eliminating the need for time-consuming sampling and laboratory tests. The measurement by the refractometer is not influenced by suspended solids or bubbles in the slurry and is selective to the liquid phase. The continuous measurement by the refractometer helps to determine extraction efficiency and to adjust process parameters. This ensures a liquid phase from the reactor with the highest possible pectin concentration.

A refractometer after the concentration step monitors the target concentration of the pectin extract to ensure its consistency. The refractometer’s output signal can be used for automated control of the concentration step, and consequently for optimizing energy consumption and alcohol usage in the following precipitation step.

The PR53A refractometer complies with the highest standards for safe food and beverage processing. The refractometer is also available with 3-A and EHEDG certifications.

Vaisala Polaris sanitary process refractometers

The Vaisala Polaris PR53AC Sanitary Compact Process Refractometer is for hygienic applications. Convenient installation directly to process lines with standard sanitary and Type N couplings, or with a sanitary flow cell. CIP and SIP cleaning.

Vaisala Polaris PR53AP Sanitary Probe Process Refractometer (pictured) is for hygienic installations in large pipes, tanks, cookers, crystallizers and kettles. The long probe with common tank bottom flanges enables installation depths of up to 170 mm. The flush mount option allows installation in tanks with scrapers or mixers. CIP and SIP cleaning.

User Interface

Vaisala Indigo520 transmitter integrates with Polaris PR53 process refractometers providing an expanded feature set, including a physical display for real-time measurement data and advanced diagnostics, more output options, data logging, and automated prism wash control. This combination enables efficient process monitoring and easy access to diagnostic information.

Measurement range

Refractive Index (nD) 1.3200 – 1.5300, corresponding to 0-100 Brix