Milk evaporation and drying

Introduction

Evaporation is one of the oldest methods for preserving milk. In this operation, water is removed from the milk to obtain a concentrated dairy product.

Depending on the process, the evaporated milk may be the desired end product, or evaporation may just be a prior step to further processing, for example, to produce sweetened condensed milk or powdered milk.

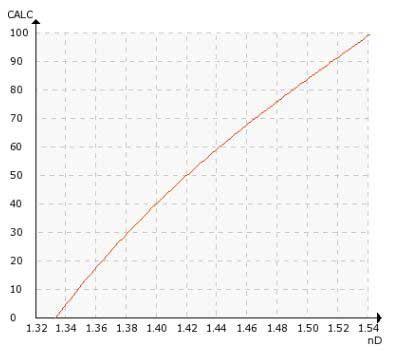

Chemical curve: R.I. per BRIX at Ref. Temp. of 20˚C

Application

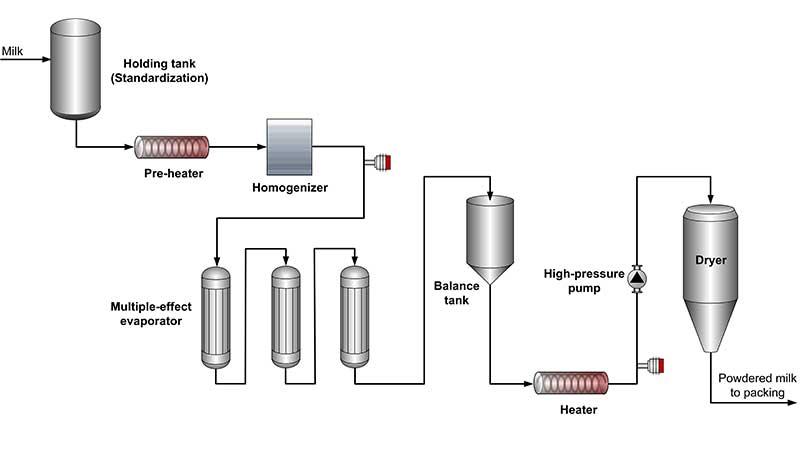

The first step in the production of unsweetened condensed milk (or evaporated milk) and powdered milk is the standardization of the fat and dry matter content of the raw milk to the level required in the final product. This is followed by a heat treatment to destroy microorganisms and to stabilize the milk. Preheating the raw milk before evaporation has a significant effect on the shelf life of the final product.

The milk is then evaporated to a specific dry solid concentration. For the production of unsweetened and sweetened condensed milk, the milk is evaporated to obtain a concentration of 30-40 % dry solids. For the production of powdered milk, the milk is concentrated to about 40-50 % dry solids for a spray dryer, and about 18 % dry solids for a roller dryer. The total dissolved solids concentration achieved in evaporation is critical as it affects the performance of subsequent operations and the quality of the final product.

After evaporation, the milk is homogenized. Homogenization reduces the mean size of the fat globules so that they are distributed uniformly in the milk and do not rise to the top creating a creamy layer. This is not a required step in the production of powdered milk, but it is applied to facilitate milk reconstitution.

The evaporated, homogenized milk then moves on to cooling, sterilization and packing for a canned evaporated milk, or to drying for a powdered milk product.

Typical end products of evaporated milk:

- unsweetened condensed milk (evaporated milk)

- sweetened condensed milk

- powdered milk

Instrumentation and installation

Vaisala Polaris Sanitary Process Refractometer PR53A provides real-time and accurate Total Dissolved Solids (TDS) measurements for better control and monitoring of the milk evaporation process. The refractometer can be calibrated to read TDS or another scale preferred by the manufacturer, e.g. Brix.

The refractometer is used for standardization after the holding tank to achieve the precise milk solids content as indicated by legal standards.

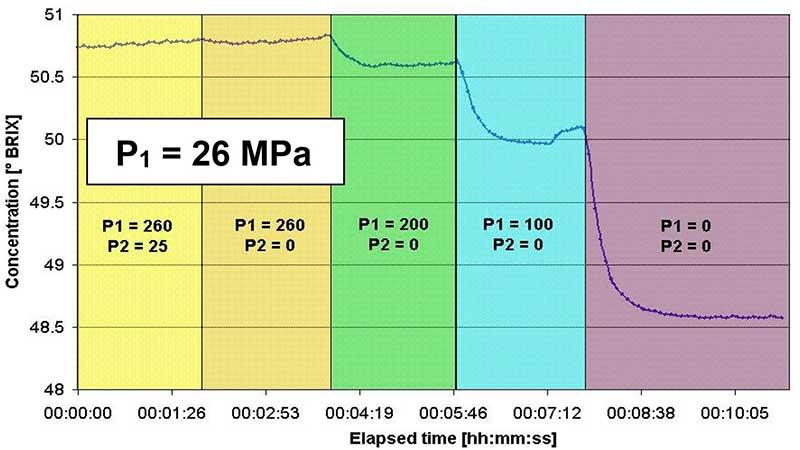

If a homogenization step is performed, a refractometer is installed after the homogenizer to include the fat content in the measurement. The refractometer detects fat globules as long as they are smaller than 6 μm. This globule size can be achieved by adjusting the pressure of the homogenizer. The recommended homogenizer’s primary pressure is P1 = 26 MPa (260 bar).

An additional refractometer between the evaporator and the high-pressure pump to the dryer allows for continuous control of the evaporation performance and dry solids concentration levels.

Accurate TDS measurement after evaporation is important in order to achieve the desired quality of the evaporated milk product and to enhance the drying operation. If the dry solids content exceeds the targeted level, the viscosity of the milk increases and creates problems with atomization during drying. Low solids content increases the energy consumption at the drying stage.

The refractometer’s self-cleaning design typically eliminates the need for a prism wash system. However, for applications involving fluids with high dry solids content above 40% or flow velocities below 1.5 m/s, an automated steam prism wash solution is recommended.

The PR53 refractometer provides a 4–20 mA output signal and supports Modbus RTU communication. When integrated with the Indigo520 transmitter, up to four 4-20mA outputs and Modbus TCP/IP connectivity are available for real-time process control. Sanitary models PR53AC and PR53AP are available with 3-A Sanitary and EHEDG certifications.

The control achieved with the precise and accurate in-line concentration measurements helps to improve end-product quality and to reduce operating costs.

Vaisala Polaris sanitary process refractometers

The Vaisala Polaris PR53AC Sanitary Compact Process Refractometer is for hygienic applications. Convenient installation directly to process lines with standard sanitary and Type N couplings, or with a sanitary flow cell. CIP and SIP cleaning.

Vaisala Polaris PR53AP Sanitary Probe Process Refractometer (pictured) is for hygienic installations in large pipes, tanks, cookers, crystallizers and kettles. The long probe with common tank bottom flanges enables installation depths of up to 170 mm. The flush mount option allows installation in tanks with scrapers or mixers. CIP and SIP cleaning.

User Interface

Vaisala Indigo520 transmitter integrates with Polaris PR53 process refractometers providing an expanded feature set, including a physical display for real-time measurement data and advanced diagnostics, more output options, data logging, and automated prism wash control. This combination enables efficient process monitoring and easy access to diagnostic information.

Automatic prism wash

For applications with sticky process conditions the prism wash options are steam wash system, pressure wash system ja water wash system.

Measurement range

Refractive Index (nD) 1.3200 – 1.5300, corresponding to 0-100 Brix.