Kraft (Sulfate) Pulp: Evaporation

Introduction

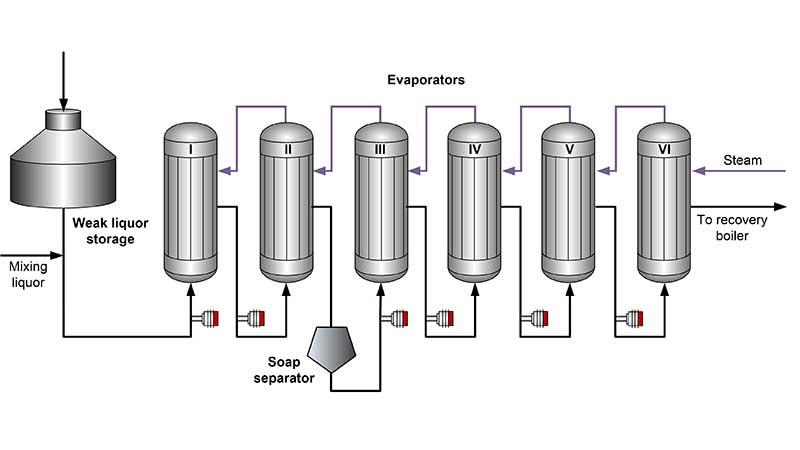

A by-product from the Kraft process is black liquor. It is a combination of removed lignin, water and chemicals used in the extraction process. The black liquor, which originates from the washing process, is concentrated through evaporation and then used to fire a boiler in order to generate high-pressure steam for the mill’s operations.

When softwood is used in pulping (e.g. conifers), a soap-like substance is collected after the process. This soap is then acidified and used to produce tall oil. Tall oil is a source of fatty acids, resin acids and various other chemicals.

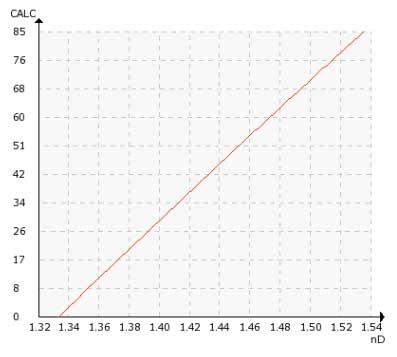

Chemical curve: R.I. per black liquor conc% at ref. temp. of 20˚C

Application

The feed to the evaporation stage should be as consistent as possible to maximize the capacity and stabilize the output concentration. Feed concentration is kept constant by regulating the mixing liquor. This is possible using Vaisala Polaris PR53SD Process Refractometer which is ideal for measuring black liquor dry solids and green liquor density or TTA in kraft chemical recovery process. for concentration measurement.

The concentration after each evaporation step can be controlled by regulating the steam flow through the evaporators. This control is achieved with the continuous measurement by the refractometer. The final concentration can also be measured. Typical operating temperature range in this application is 120- 130 ºC (248-266 ºF).

It is recommended to measure the liquor concentrations at intermediate evaporation stages to minimize total steam consumption. This is particularly important in mills where the cost of steam is high.

Typical black liquor end products:

- wood pulp

- paper

- board

Instrumentation and installation

Typical concentration at the evaporation feed is 10 to 30 % dry solids and after the concentrator phase 60 to 80 % dry solids.

Automatic prism wash with steam is recommended for evaporation installations.

When handling high solids concentrations above 80% - for example in black liquor from acacia or eucalyptus hardwood, the high-range prism option is recommended. This option covers a wider refractive index range, as in these cases the refractive index may exceed 1.53 nD.

Vaisala Polaris™ PR53SD Process Refractometer

The Vaisala Polaris PR53SD Process Refractometer model is for the toughest process conditions in the pulp industry, measuring black liquor, green liquor, brown stock washing and other liquid concentrations in the fiber and chemical recovery lines.

Diagnostics for prism wash

Advanced optical image analysis and diagnostics help users to quickly analyze wash performance.

Measurement range

- Refractive Index (nD) 1.32–1.53 nD (0–90 % total solids), normal-range prism

- Refractive Index (nD) 1.36–1.57 nD (20–100 % total solids), high-range prism