Infant formula production by the wet-mixing process

Introduction

Baby milk, or infant formula, is a substitute for breast milk. It is available as either a dried powder, or as a ready-to-use canned or bottled liquid. Regardless of the type, all formulas contain a protein source, a fat source, a carbohydrate source and added supplements.

Infant formula can be manufactured by a wetmixing process where all ingredients are handled in liquid form, a dry-blend process where ingredients are blended as powders, or a combination of these processes.

Wet-mixing is the most used technology as it ensures control over the milk’s composition and microbiological safety. The formula’s composition should be carefully monitored to achieve a high-quality product that matches as close as possible to breast milk, and which is safe for infant consumption.

Application

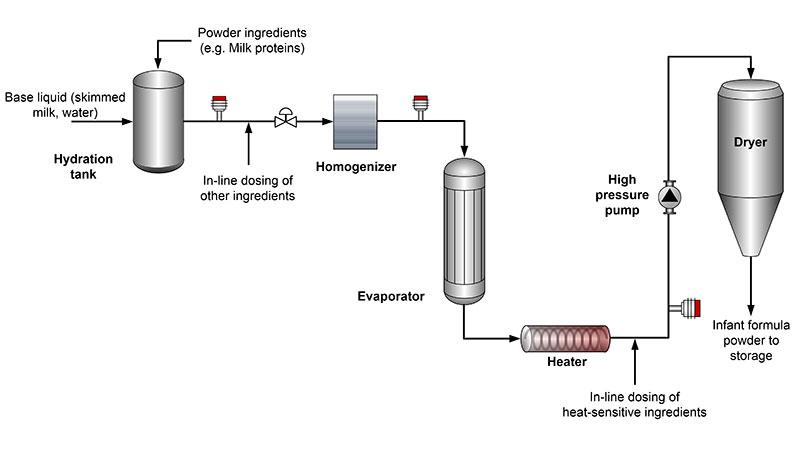

The wet-mixing process involves three stages: preparation of the mix, evaporation and drying. For the preparation of the mix, the base liquid can be water or skimmed milk. Other water-soluble powder ingredients are added to the base liquid (e.g. milk proteins) and the resulting mixture is stored in a large vessel for complete hydration.

A homogenization step follows to increase the uniformity and stability of the emulsion by reducing the size of the fat and oil particles in the formula.

Evaporation of the milk mixture is an essential step that enhances the spray-drying operation and increases the final product shelf life. Other ingredients, which are heat-sensitive, are added after evaporation.

Finally, the concentrated milk is typically dried in a spray-dryer system. The temperature as well as the solids content of the milk mixture are kept as high as possible for maximum efficiency. Low solid content results in small particle size, as well as poor wettability and short self life of the final product. Excessively high dry solids content increases the milk’s viscosity which results in larger particles and affects the spray dryer capacity

Typical end products of infant formula

- powdered infant formula

- powdered baby milk.

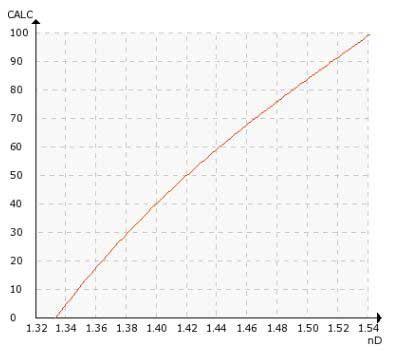

Chemical curve: R.I. per BRIX at Ref. Temp. of 20˚C

Instrumentation and installation

Vaisala Polaris™ PR53AC Process Refractometer is the ideal in-line measurement instrument for safe, higiene and accurate manufacturing of infant formula. The refractometer is available with 3-A Sanitary and EHEDG certifications. It is designed to withstand CIP and high process temperatures. Moreover, the refractometer can be calibrated to measure either Brix, dry solids, or Total Dissolved Solids (TDS).

A refractometer is installed after the hydration tank to measure TDS content. This ensures the right inline dosing of other ingredients to meet the recipe requirements.

A second refractometer after the heater monitors the dissolved solids content. This helps to determine the right dose of heat-sensitive ingredients and ensures that the right concentration is fed to the dryer. Solid content prior drying is critical to optimize the spray dryer performance, energy consumption and final product quality.

A third refractometer can be installed before the evaporator for maximum evaporation performance control. When the products contain fat or oil, the refractometer should be installed after the homogenizer where the fat globules break down to a smaller size. The refractometer detects fat globules as long as they are smaller than 6 μm.

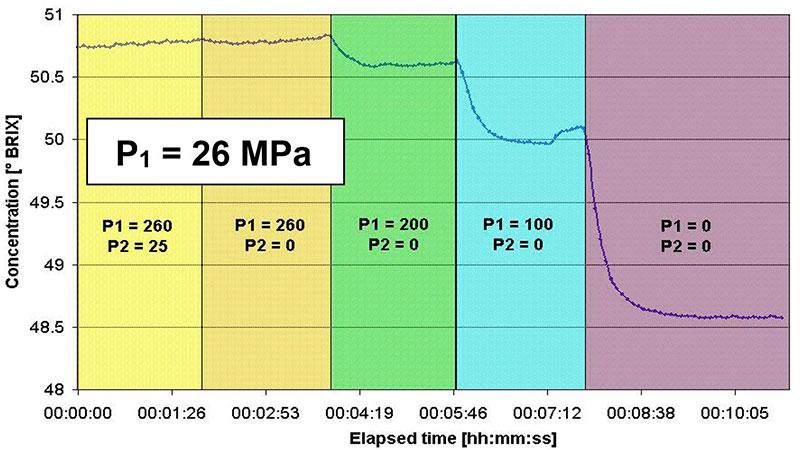

The pressure in the homogenizer can be adjusted to obtain this globule size. The higher the pressure the smaller the globule. The recommended homogenizer’s primary pressure is P1 = 26 MPa (260 bar).

Typically, prism wash is not required for any of these applications. However, a steam prism wash solution using Process Refractometer PR53A, aseptic steam ASV valve, and a side flow cell is required for low velocities or for fluids with a dry solid content above 40 %.

The refractometer is a stand-alone device capable of operating independently or with one of several different user interface options. It provides an Ethernet or 4-20 mA output signal for real-time process control.

The accurate control achieved with the precise in-line concentration measurements ensures a high quality and safe end product, as well as optimized operating costs.

Vaisala Polaris Sanitary Process Refractometers

The Vaisala Polaris PR53AC Sanitary Compact Process Refractometer is for hygienic applications. Convenient installation directly to process lines with standard sanitary and Type N couplings, or with a sanitary flow cell. The product is also compatible with clean-in-place (CIP) and sanitation-in-place (SIP) systems.

Vaisala Polaris PR53AP Sanitary Probe Process Refractometer (pictured) is for hygienic installations in large pipes, tanks, cookers, crystallizers and kettles. The long probe with common tank bottom flanges enables installation depths of up to 170 mm. The flush mount option allows installation in tanks with scrapers or mixers. The product is also compatible with clean-in-place (CIP) and sanitation-in-place (SIP) systems.