Coffee and tea extraction, evaporation and recovery

Introduction

Coffee and tea are the most consumed beverages worldwide after water. Coffee and tea are traditionally prepared by brewing coffee beans or tea leaves, respectively. Today, coffee and tea are available as instant powder for easier and quicker preparation.

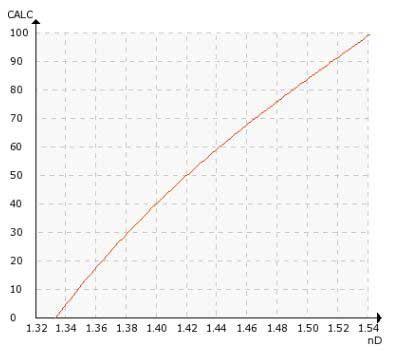

Chemical curve: R.I. per BRIX at Ref. Temp. of 20˚C

Application

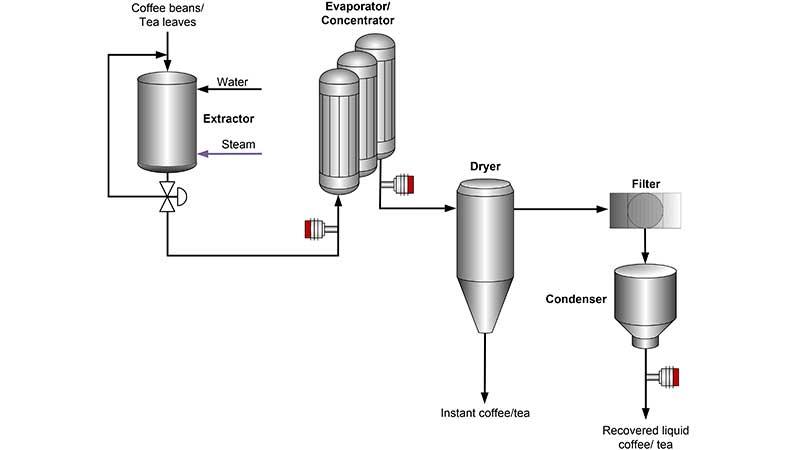

extraction process. Coffee beans are boiled in water to extract the soluble solids. The coffee extract is evaporated and dried either by spray drying or freeze drying.

A spray dryer is sometimes preferred as it produces fine, rounded particles. In the spray dryer, the concentrated coffee is atomized by a nozzle and warm air is fed to the tower to dehydrate the droplets into particles. Some of the coffee exits the tower with the air. This coffee dust passes through a filter to recover the solids. The coffee is dissolved in steam, and the recovered liquid coffee extract is returned to the process.

Tea leaves go through the same process as coffee beans: extraction, concentration and spray drying. The most difficult part in the instant tea process is aroma preservation.

Typical examples of soluble coffee and tea solids' end products are:

- instant coffee

- tea extract

- instant tea

Instrumentation and installation

Vaisala Polaris™ PR53A Process Refractometer is used for accurate concentration measurement of soluble solids at different stages of the process.

The refractometer is used as a reliable and real-time indicator of extraction efficiency. Typical measurement range is 0-30 Brix and the normal process temperature is 5 ºC (41 ºF). Prism wash with high-pressure hot water is recommended in this point.

At the evaporators, the refractometer is used to ensure that the desired concentration is fed to the dryer, thus optimizing the energy consumption. The evaporation is a triple-stage process, with stage concentrations consisting of 10-20 % dry solids, 15-30 % dry solids and 35-65 % dry solids. Under normal circumstances the process temperature is 52-82 ºC (126-180 ºF). Prism cleaning with steam is recommended at the evaporator outlet.

The refractometer is also used to measure the concentration of recovered instant coffee dust after filtration. Typical measurement range is 8-20 Brix and the normal process temperature is 75-85 ºC (167 185 ºF).

Vaisala Polaris sanitary process refractometers

The Vaisala Polaris PR53AC Sanitary Compact Process Refractometer is for hygienic applications. Convenient installation directly to process lines with standard sanitary and Type N couplings, or with a sanitary flow cell. CIP and SIP cleaning.

Vaisala Polaris PR53AP Sanitary Probe Process Refractometer (pictured) is for hygienic installations in large pipes, tanks, cookers, crystallizers and kettles. The long probe with common tank bottom flanges enables installation depths of up to 170 mm. The flush mount option allows installation in tanks with scrapers or mixers. CIP and SIP cleaning.

User Interface

Vaisala Indigo520 transmitter integrates with Polaris PR53 process refractometers providing an expanded feature set, including a physical display for real-time measurement data and advanced diagnostics, more output options, data logging, and automated prism wash control. This combination enables efficient process monitoring and easy access to diagnostic information.

Automatic prism wash

For applications with sticky process conditions the prism wash options are steam wash system, pressure wash system ja water wash system.

Measurement range

Refractive Index (nD) 1.3200 – 1.5300, corresponding to 0-100 Brix.