vH2O2 bio-decontamination measurement, monitoring and control

Effective processes, cycle development, and validation

Vaporized hydrogen peroxide is a safe and environmentally friendly way of performing bio-decontamination in isolators, hospital rooms, transfer hatches and other applications. Vaporized H2O2 concentration levels and other parameters are measured during bio-decontamination to provide in-process control and ensure process conditions have been achieved.

To maintain sensor accuracy over multiple bio-decontamination processes, the PEROXCAP sensor has two internal features: sensor warming and purge function. The warming prevents condensation on the sensor and the purge function cleans the sensor membrane from potential contaminants. The intelligent measurement technology of the HPP270-series probes helps maintain measurement accuracy between calibration intervals – even in challenging, high-humidity bio-decontaminations.

- Isolators, cRABS

- Transfer Hatches & chambers

- Vapor generators

- Incubators and chambers

- Production lines

H2O2 Measurement: Relative Saturation

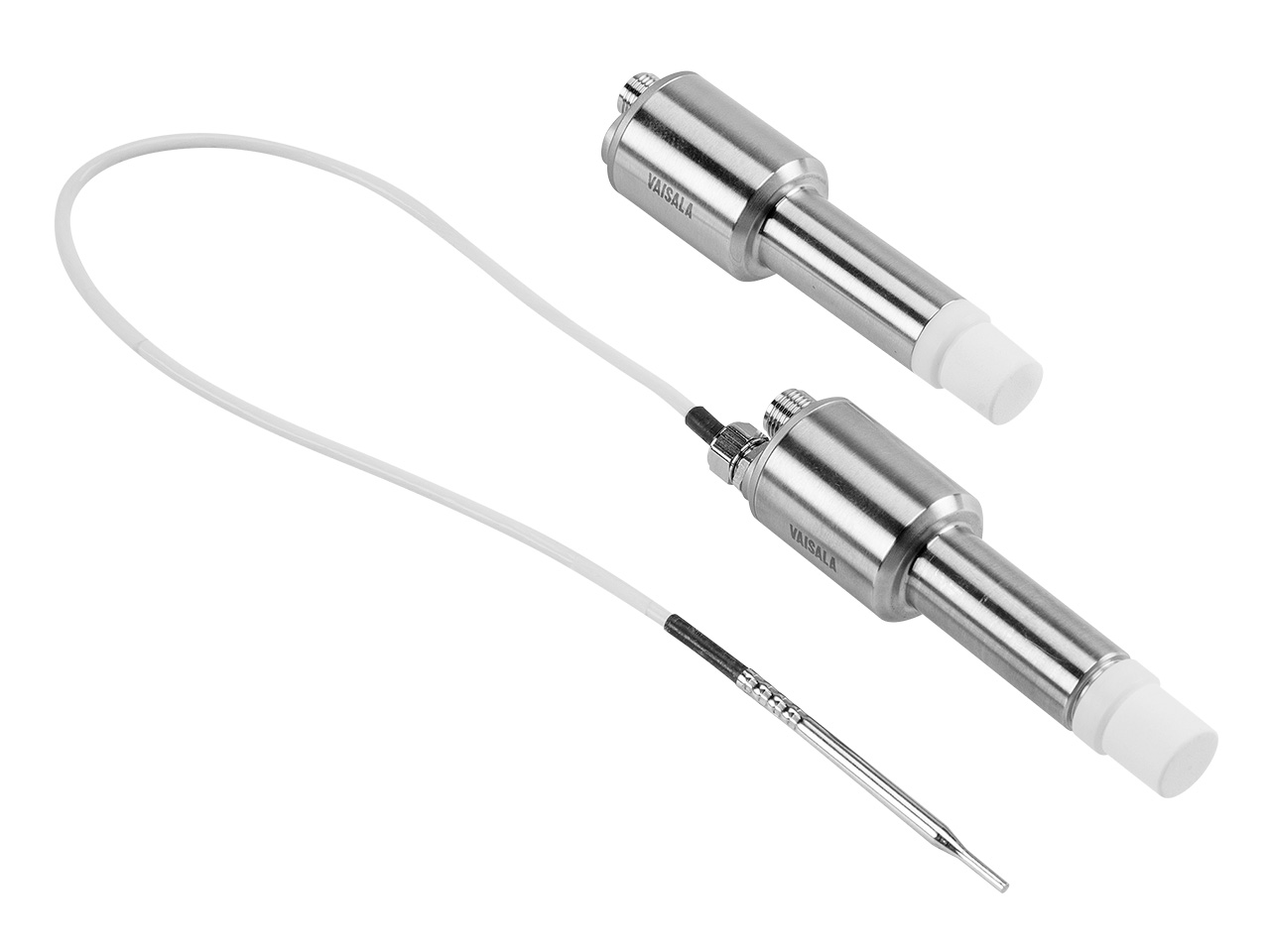

PEROXCAP® sensor technology uses two HUMICAP® sensors; one is a standard HUMICAP sensor and the other includes a catalytic layer that prevents H2O2 molecules from entering the sensor membrane and senses only the water vapor part of the air mixture. The HPP272 probe has an additional RTD temperature probe to monitor process temperature with humidity (both relative humidity and relative saturation). Dew point and vapor pressure measurements are possible, often critical parameters in bio-decontamination. The HPP271 probe option measures H2O2 ppm by volume.

Benefits of PEROXCAP®

- Unique capacitive thin-film polymer sensors for repeatable measurement

- Stable even in high humidity bio-decontamination conditions

- Multiple measurements from a single device

- Onsite calibration or traceable factory calibration

The Vaisala PEROXCAP® HPP270 series probes

The Vaisala PEROXCAP® HPP270 series probes feature both digital and analog outputs. In addition to H2O2, the probe measures temperature and humidity, referring to relative saturation and relative humidity, dew point, and vapor pressure. The probes can be used for both monitoring and control. Another unique feature of the HPP270 series probes is the ability to evaluate the sensors’ performance through its “Sensor Vitality” value. This value provides on-going diagnostics on sensor function.

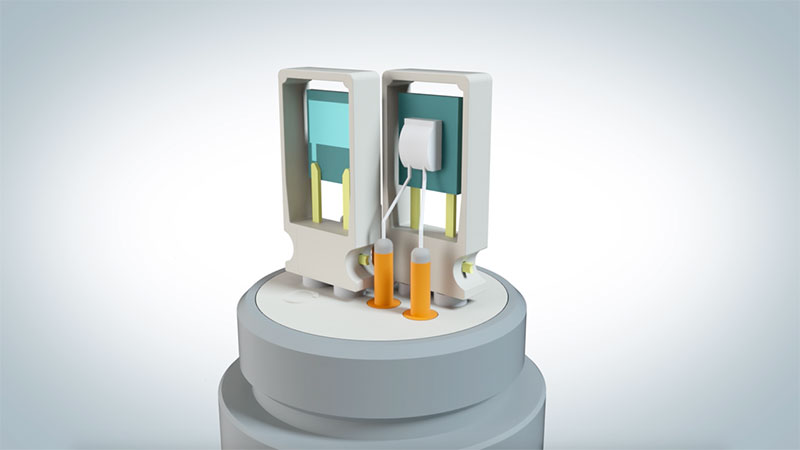

The probes can be used with the optional Vaisala Indigo transmitters or as standalone probes. Indigo transmitters provide an easy user interface and can be configured according to process requirements. Indigo comes with plug-and-play probe connection, LCD color display (optional non -display version for analog model), and IP65 enclosure. For simple probe configuration, calibration, and adjustment, the probe can be connected to Vaisala's Insight PC software.

vH2O2 Calculator

With this vaporized hydrogen peroxide calculator, you can simulate bio-decontamination processes in closed and open systems, or under free evaporation conditions. Simply choose your method and input parameters like: phase duration, temperature, injection rates, H2O2 liquid concentration, and other parameters. Model your process in the simulator and see the effects on the condensation point, relative humidity, relative saturation, and achievable vH2O2 ppm concentration.

How to use:

- Choose your bio-decontamination method: Closed system, Open system, free evaporation

- Enter process parameters

- View results

See also our webinar on using the vH2O2 calculator

Vaporized Hydrogen Peroxide Measurement related products

Vaporized Hydrogen Peroxide, Humidity and Temperature Measurement HPP270 Series

Indigo500 Series Transmitters

Indigo200 Series Transmitters for Vaisala smart probes