Vaisala and Via Separations: Measuring success with advanced black liquor technology

The client: Via Separations

Vaisala solution: PR23SD process refractometers for inline TDS monitoring

Innovative membrane filtration system at International Paper’s Grande Prairie mill demonstrates 76% energy reduction with critical support from Vaisala’s inline black liquor monitoring solution

When Via Separations set out to commercialize a groundbreaking membrane technology for black liquor concentration in pulp mills, the company knew proving the system’s performance would be paramount. For decades, mills have relied on massive evaporators that boil water from a thick, caustic mixture of organics and inorganics before recovery, consuming significant steam, creating capacity bottlenecks and, ultimately, driving operating costs upward.

Via Separations’ innovation promised energy savings and chemical cost reductions, but it had never been deployed at a commercial scale. Accurate, reliable measurement of total dissolved solids (TDS) throughout the process would be critical to measuring Via’s performance.

The Challenge: Proving a first-of-its-kind technology

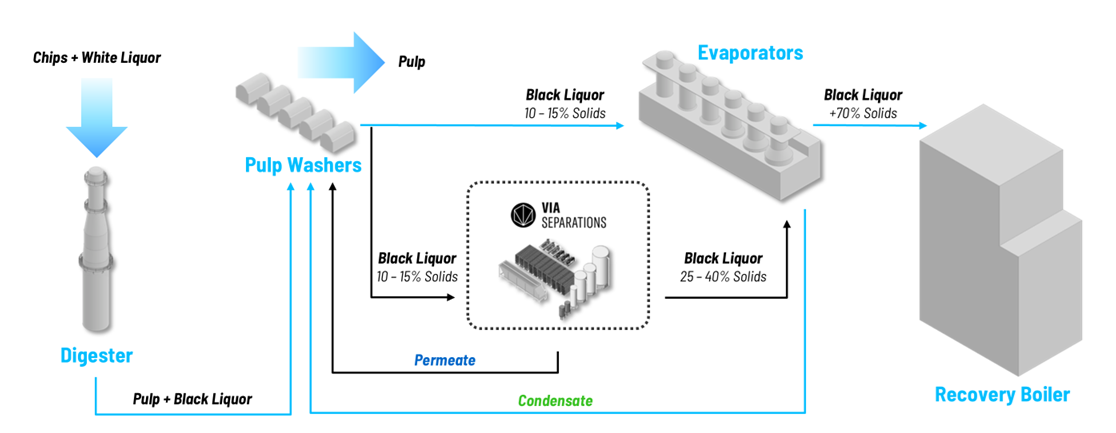

Black liquor — the caustic byproduct of kraft pulping that resembles “tree soup” — poses unique measurement challenges. It’s a viscous, corrosive fluid that contains organic molecules from wood, sodium hydroxide and other inorganic compounds at pH levels around 13 and temperatures reaching 180 degrees F. As it travels from the digesters and washers to the evaporators and finally to the recovery boilers, black liquor must be concentrated from roughly 15% dissolved solids to over 70% before it can be burned in a recovery boiler.

Traditional evaporation systems achieve this concentration by boiling off water, an energy-intensive thermal process that accounts for significant steam usage in pulp mills. But evaporators are frequently the biggest steam user outside of the paper machines at the mill and a common production bottleneck. If upstream solids drop, evaporators struggle to keep up, losing efficiency and reliability.

Via Separations developed a membrane-based alternative using graphene oxide technology that mechanically separates water from solids, bypassing the need to induce phase change through heat.

The concept was promising. Pilot testing revealed Via's filtration system reduces energy use and capital/operating costs significantly. But no one had successfully implemented membranes in black liquor concentration before.

The Approach: Continuous inline monitoring with Vaisala refractometers

Via Separations needed instrumentation that could withstand the harsh industrial environment while delivering precise, continuous measurements to demonstrate membrane performance. Based on positive previous experience with Vaisala refractometers in similar applications, the team selected the PR23SD process refractometer.

Via’s innovative system installed three Vaisala refractometers at strategic points to provide complete visibility into system performance:

- Monitoring feed entering the membrane system.

- Tracking concentrate exiting the membrane system.

- Measuring permeate (the separated clean water) to verify quality.

The refractometers use advanced optical measurement technology to determine total dissolved solids concentrations by measuring the refraction of light in the process liquid — a measurement that correlates directly to dissolved solids content. Even better, the sensors can handle the extreme conditions of black liquor: high temperatures, caustic pH and fiber content that would compromise many other measurement technologies.

Critically, Via Separations required near 100% uptime with minimal operator interaction. Vaisala’s self-cleaning sensors help keep measurement surfaces clear, enabling continuous operation with minimal maintenance, complementing Via’s highly durable membranes which, at the time of publication, have demonstrated 18 months of lifetime.

The Results: Reliable performance, proven at scale

Construction of the Grande Prairie system was completed in 10 months. The facility, consisting of over 600 membrane modules, integrated the system into International Paper’s operations with zero downtime and began operations in May 2024.

From installation, Vaisala’s continuous monitoring data allowed Via Separations to prove its technology’s performance. Continuous measurements confirmed the system was delivering on its energy efficiency promise, using 76% less energy per gallon of water removed than traditional evaporators. This efficiency translates to avoiding one ton of fossil fuel CO₂ emissions every 80 minutes, or roughly 6,500 metric tons per year for a second-generation installation.

But the value extended beyond energy savings. Continuous monitoring revealed how membrane performance varied as black liquor feed characteristics changed — critical information for optimizing throughput. The data showed something unexpected and advantageous: The membranes produced up to 93% more permeate flow during low-solids events, exactly when mills need additional water removal capacity most during upsets or startups.

Continuous TDS monitoring allows for real-time measurement of membrane health, allowing for optimization of membrane cleaning recipes and frequencies to fine-tune operations and maximize value delivery. The result? Millions in annual chemical savings when deployed at full scale.

With membrane lifetimes up to 18 months demonstrated at this deployment, Vaisala’s sensor accuracy became crucial for detecting subtle changes in membrane rejection over time. Minor variance in membrane performance would manifest as small changes in the concentrate or permeate dissolved solids levels — changes that required precise measurement to detect and characterize.

The ability to accept custom calibration curves proved particularly valuable. Via’s membrane system removes black liquor components progressively, creating process intermediates with different component ratios than the feed. By developing custom calibrations with actual process samples, Via Separations ensured each measurement point delivered maximum accuracy tailored to its specific stream composition.

This level of measurement precision gives customers confidence in the technology. Over the first year of operation, the system logged more than 10,000 operating hours with over 90% uptime. Continuous TDS data helped Via Separations demonstrate reliability to a customer to de-risk its first-of-its-kind commercial deployment.

The successful Grande Prairie installation validated membrane technology for an application long considered impossible. The North American evaporator fleet has a median age of 44 years, with many facilities facing major capital decisions about aging equipment. Via Separations’ technology — enabled by reliable process monitoring — offers an alternative: lower capital expenditure, dramatically higher energy efficiency, and improved operational flexibility.

The partnership between Via Separations and Vaisala demonstrates how advanced measurement technology drives industrial innovation. Without continuous, accurate dissolved solids monitoring, Via Separations couldn’t have proven its system’s performance or optimized its operation. The data did more than validate the technology — it revealed operational characteristics that create new value-add opportunities for process improvement.

As Via Separations expands to additional pulp mills and explores applications in adjacent industries, Vaisala’s refractometers remain integral to system design and operation. The measurement infrastructure that helped prove the first system now enables each new installation to deliver consistent, documented performance from day one.

For pulp mills facing pressure to reduce emissions or operational constraints, the Grande Prairie installation offers a compelling proof point. Membrane-based concentration is operating, it’s reliable, and it’s delivering measurable results that wouldn’t be possible without the continuous, accurate monitoring that Vaisala’s instrumentation provides.

Graphs and images credits: Via Separations

Learn more

Explore how Vaisala supports black liquor concentration and chemical recovery processes

Learn more about Vaisala measurement solutions for the pulp, paper and wood industry